Filternox® offers innovative filtration solutions to maximize your gold recovery during ultrasonic cleaning.

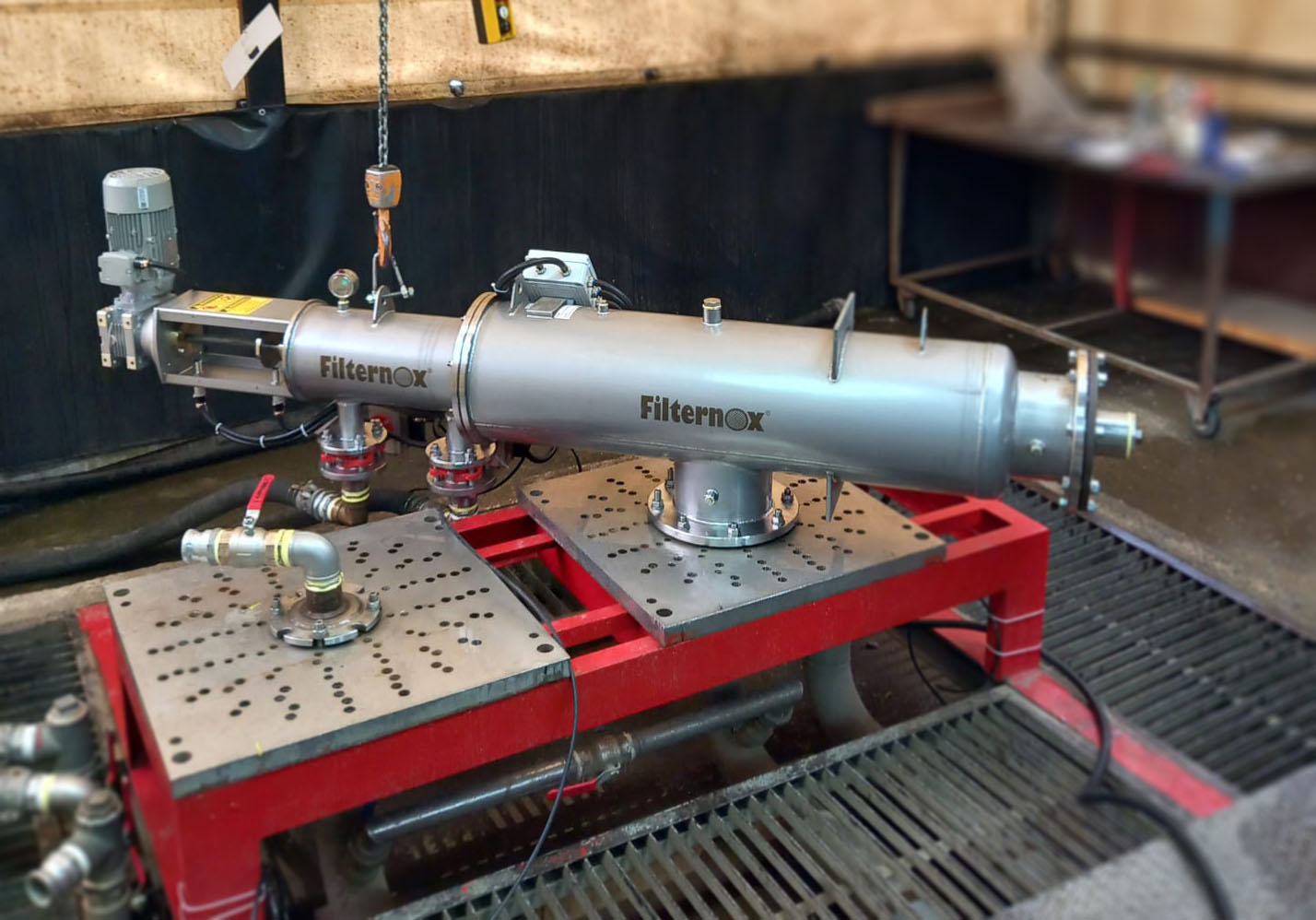

Image 1.1. Filternox Pilot Filtration System Image

Cooling tower water filtration test with drum filter, hydrocyclone and Filternox® FMS-MR model automatic self cleaning filters.

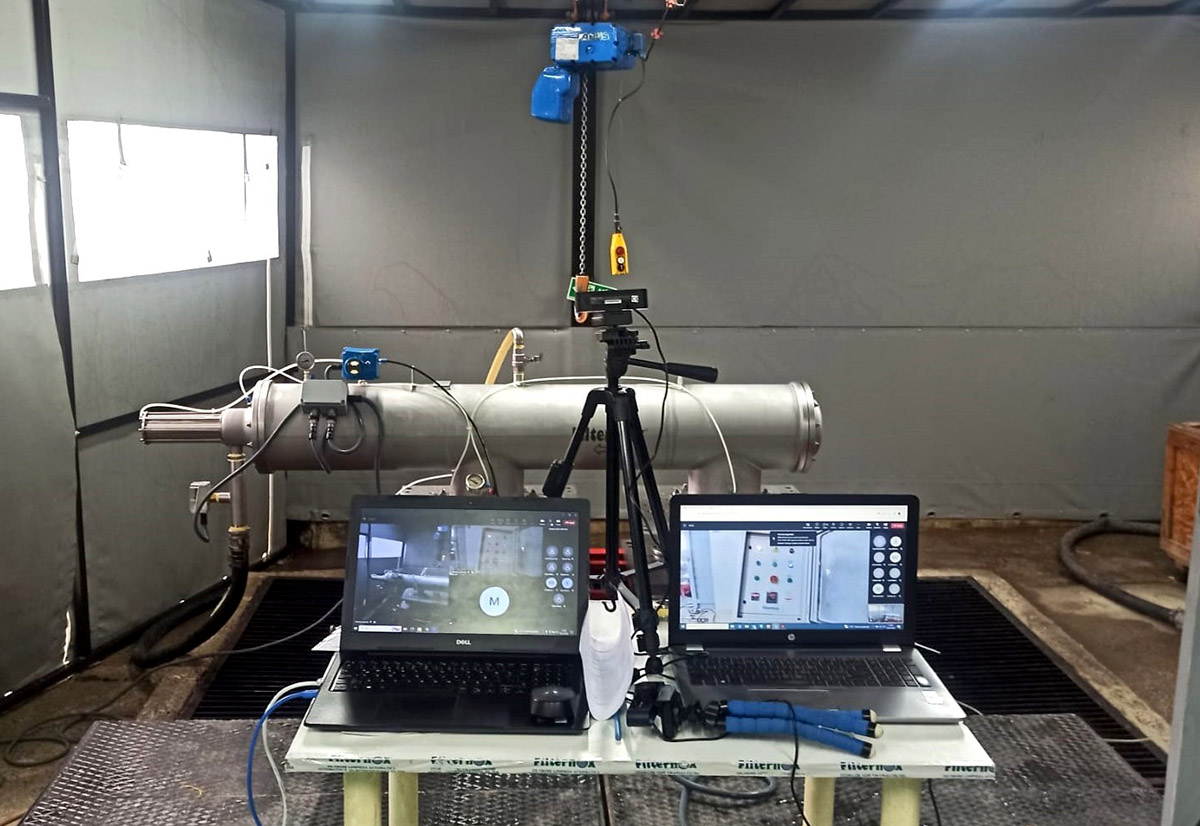

The Filternox Engineering team conducted a comprehensive Cooling Tower Water Filtration Test, evaluating the performance of a drum filter, a hydrocyclone, and Filternox® FMS-V-MR model automatic self-cleaning filters. The primary objective of the test was to compare the pre-filtration capabilities of the hydrocyclone and the drum filter prior to the final filtration stage using the FMS-MR model filters.

A series of filtration tests were conducted at a leading steel production company over a 5-day period, commencing on December 25, 2023. During the 5-day period, the efficiency tests were conducted on Drum Filter and Hydrocyclone at different microns and flow rates. These tests were completed with Filternox® Drum Filter and Filternox® Hydrocyclone at flow rates of 10-15-20 m3/h.

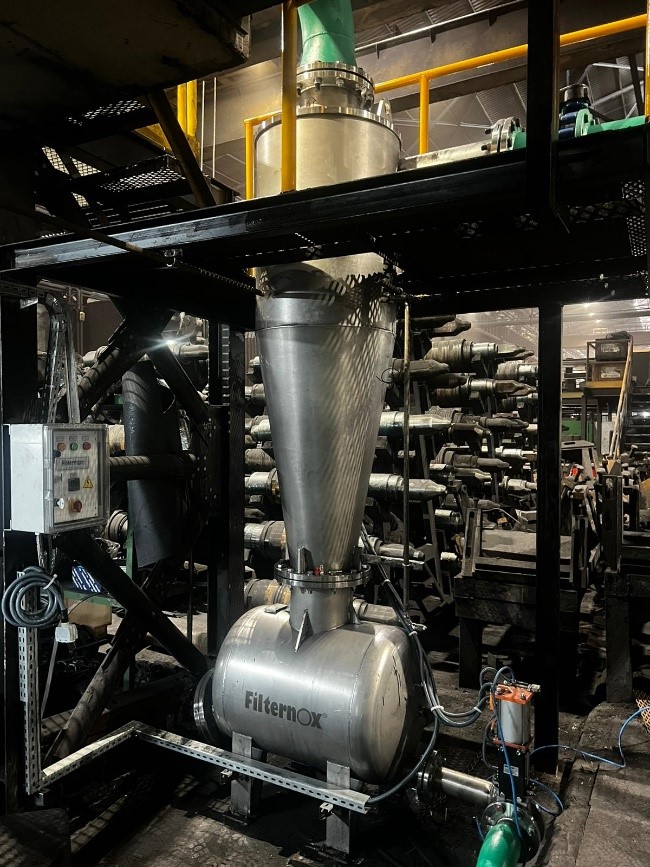

Following extensive testing, the Technical Management of Steel-Iron Industry Company opted to implement the hydrocyclone application prior to the installation of automated Self-Cleaning Filternox Filters. In response to the client’s specifications, Filternox Engineering designed a hydrocyclone with a 200 m3/h capacity, which was subsequently manufactured entirely from duplex stainless steel.

Image 1.2. View of completely duplex stainless steel hydrocylone

Image 1.3. |

Image 1.4. |

Image 1.5. Image of the SPT-SBV-MR Model Skid Mounted System Located After the Hydrocyclone

| Application | Filtration of Leachate Water |

| Project Location | ISTAC- Sile/ Leachate Treatment Plant |

| Filter Model | SPT-PBV-MR Model Automatic Self-Cleaning Filter |

| Filtration Level | 1,5 mm |

| Flow | 255 m3/h / filter |

| Design Pressure / Working Pressure | 10 bar / 1,2 bar |

| Filter Body / Element Material | AISI 316L /AISI 316L |

| Filter Quantity | 4 units |

| Control Panel Quantity | 2 units |

| Application | Sea Water Filtration Prior Heat Exchanger |

| Project Location | Hong Kong |

| Filter Model | ACF-MR Model Automatic Self-Cleaning Filter |

| Filtration Level | 1,7 mm |

| Flow | 684 m3/h / filter |

| Design Pressure / Working Pressure | 10 bar / 10 bar |

| Filter Body Material | AISI 316L with Internal Epoxy Painting and Zinc Anode Protection |

| Filter Element Material | AISI 316L |

| Filter Quantity | 3 units |

American brand filters were replaced with Filternox® filters one year ago. After one year of working period, condition of the filter regarding maintenance, corrosion protection and filtration efficiency are perfect.

Old American brand filter. One year ago. |

Filternox Duplex SS filter |

Contaminant type |

Corrosion protection |

| Customer | Iron-Steel Industry |

| Application | Sand Filter Inlet- Outlet Water Filtration |

| Water Source | Treated Waste Water |

| Test Flow | 5 m³/h |

| Test Date | 22 January 2024 |

The Filternox Engineering and Testing Team was present at the Iron-Steel Factory facility from January 22nd for a duration of 1 day to conduct filtration tests. The inlet water of the sand filter was tested with the Filternox® FMS-V-MR Model filter with a 40-micron rating, and the outlet water was tested with the Filternox® FMS-V-MR Model NTU Terminator filter. The data obtained from the measurements has been documented and reported.

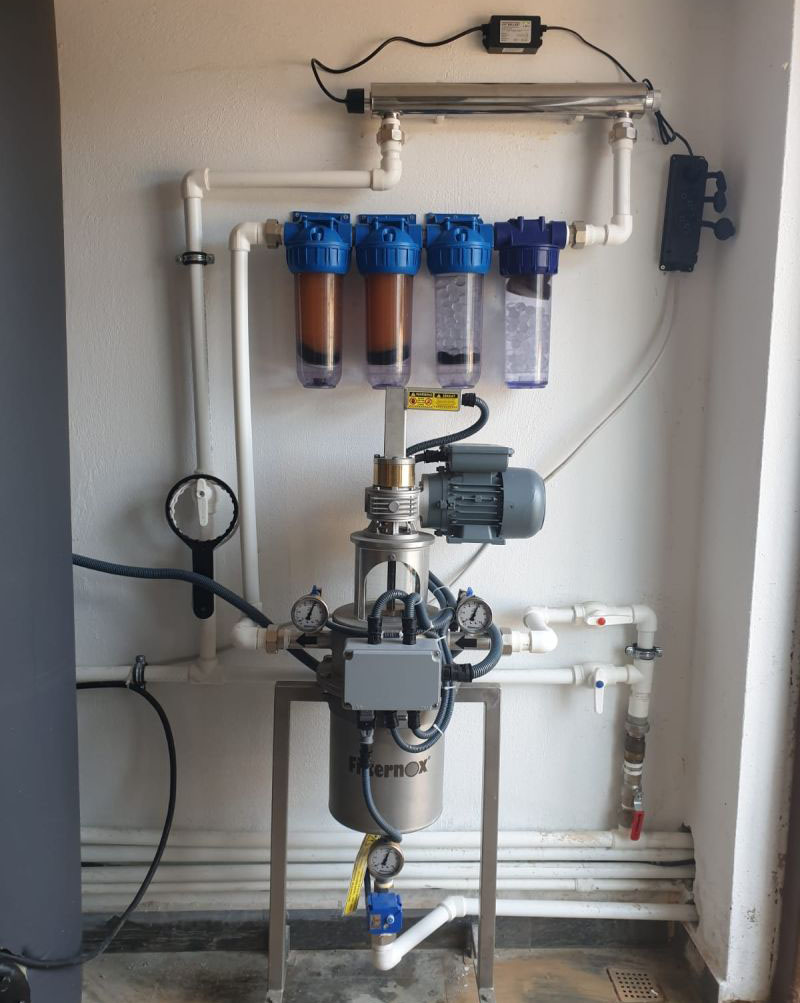

Picture 1.1. Filtration System Image

Picture 2.1. Filternox® 40 Micron FMS-V-MR Model Filter Sample Measurement Results

Picture 2.2. Filternox® NTU Terminator FMS-V-MR Model Filter Sample Measurement Results

If the water sample’s TSS value is under 0 ppm , an underrange result is obtained.

These effects briefly include:

The disappearance of glaciers in the mountains, consequently leading to a decrease in the flow of rivers and a reduction in freshwater sources, deteriorating water quality.

The disappearance of glaciers in the mountains, consequently leading to a decrease in the flow of rivers and a reduction in freshwater sources, deteriorating water quality. The complete melting of all glaciers would significantly raise sea levels. The rising water levels would lead to the salination of underground resources and necessitate much more extensive use of RO systems.

The complete melting of all glaciers would significantly raise sea levels. The rising water levels would lead to the salination of underground resources and necessitate much more extensive use of RO systems. Global warming affects the hydrological cycle (precipitation, evaporation, and condensation), which could increase the risk of drought in some areas, while in other areas, it could lead to increased risks of excessive rainfall and flooding. These changes lower the underground water level and degrade water quality.

Global warming affects the hydrological cycle (precipitation, evaporation, and condensation), which could increase the risk of drought in some areas, while in other areas, it could lead to increased risks of excessive rainfall and flooding. These changes lower the underground water level and degrade water quality. Increased temperatures and changing rainfall patterns lead to the pollution of water resources and a decline in water quality. For example, excessive temperatures encourage the growth of harmful algae in water sources, which reduces the level of dissolved O2, putting pressure on the life of other organisms.

Increased temperatures and changing rainfall patterns lead to the pollution of water resources and a decline in water quality. For example, excessive temperatures encourage the growth of harmful algae in water sources, which reduces the level of dissolved O2, putting pressure on the life of other organisms. Rising temperatures and changes in precipitation regimes increase the need for irrigation in agricultural areas. This puts extra pressure on already limited water resources. Therefore, modern systems should be used in agricultural irrigation to minimize water usage. All of the possibilities mentioned above will greatly increase global inflation and impose a heavy burden on low-income groups, as well as significant additional costs for all countries.

Rising temperatures and changes in precipitation regimes increase the need for irrigation in agricultural areas. This puts extra pressure on already limited water resources. Therefore, modern systems should be used in agricultural irrigation to minimize water usage. All of the possibilities mentioned above will greatly increase global inflation and impose a heavy burden on low-income groups, as well as significant additional costs for all countries.

We should all save water and reuse it, regardless of the amount.

At Filternox, we spend a percentage of each sale on research and development.

| Application |

Glass mold water filtration for protection |

| Water Source |

Process water |

| Filter Model | SFH-MR Skid mount system |

| Filtration Level | 50 micron |

| Flow |

25 m3/h / filter |

| Design Pressure / Working Pressure |

10 bar / 6 bar |

| Material: Filter Body / Element |

AISI 304L / AISI 316L |

| Filter Quantity | 2 |

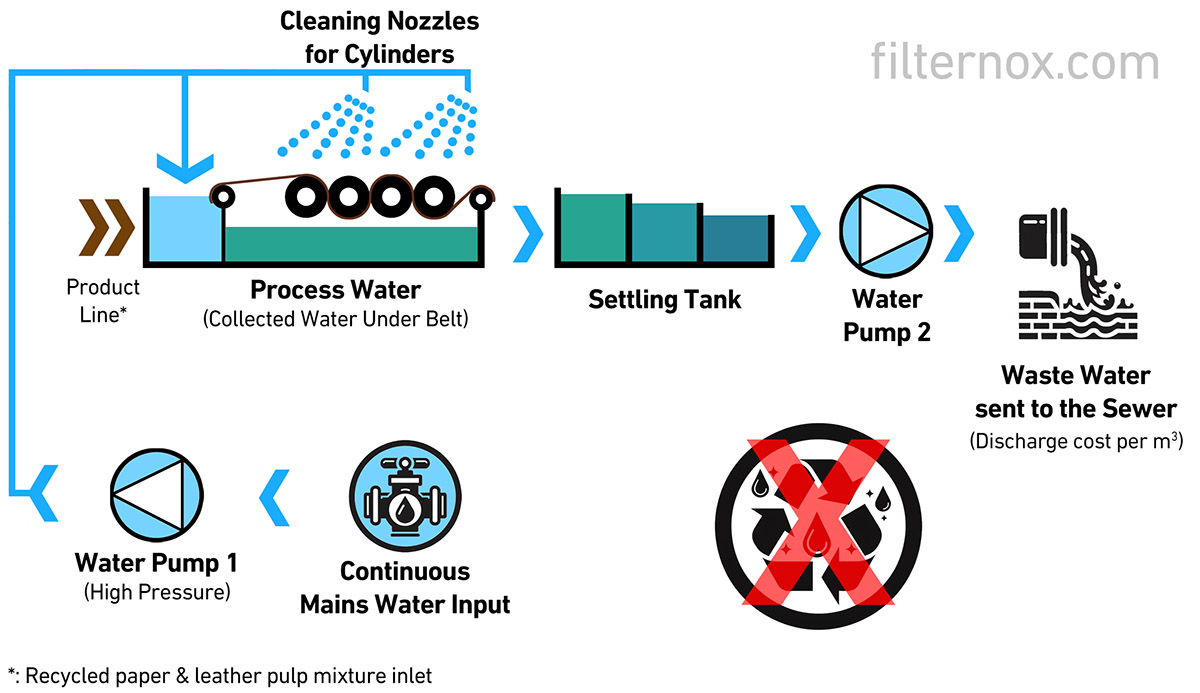

The primary objective of this case study is to compare the performance and cost implications before and after the installation of Filternox® Automatic Self-Cleaning water filters on the leather board machine to recycle water and for nozzle protection.

The focus is particularly on rapid return on investment and green environmental solutions.

+ High consumption of city mains water.

+ Environmental impact due to wasteful water consumption.

+ Regular maintenance and potential wear on nozzles due to water quality issues.

+ Significant operational costs related to water usage.

+ High operational expenses associated with the discharge of wastewater in the industrial zone.

Before the installation of Filternox® water filters, the leather board machine directly utilized city mains water, leading to a considerable cost every month. This inefficient practice resulted in substantial recurring expenses associated with the disposal of dirty water, contributing to ongoing operational costs.

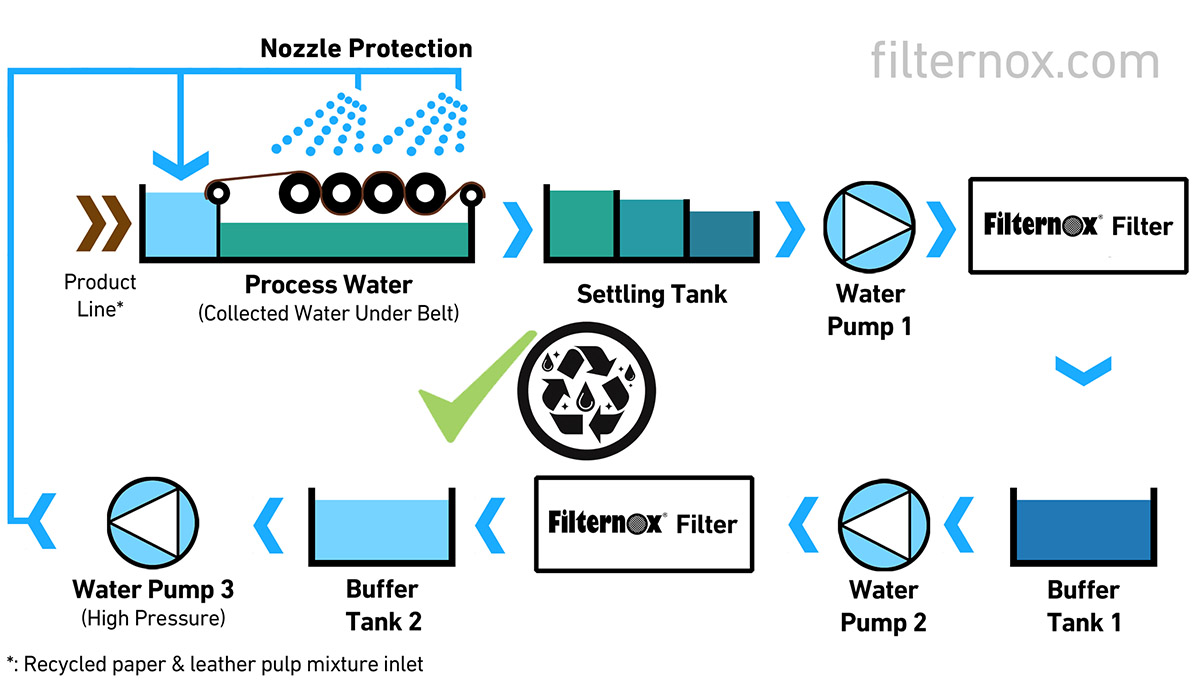

+ Significantly reduced reliance on mains water.

+ 24/7 nozzle protection.

+ Improved environmental sustainability through water recycling.

+ Compared to the time before installation, there is a substantial reduction in wastewater discharge and the associated industrial zone fees.

+ Rapid return on investment, achieved in approximately two months.

+ Daily water savings is comparable to water consumption of a small town with 6000 residents.

Filternox® Filters stand out as a highly efficient and rapidly self-redeeming investment. The leading leather board manufacturing company in this case experienced annual savings of approximately €135,000 by installing the Filternox® Filters. Beyond the substantial economic benefits, the environmental impact is noteworthy, as the system contributes significantly to water conservation, preventing wasteful discharge into sewage and positively affecting our sustainable future.

| Daily Water Saving | 1.400 tonnes |

| Annual Water Saving | 369.600 m3 |

| Water Price per m3 | €0.3648 |

| Annual Total Amount Saved | €134.830 + Industrial zone waste discharge fees |

This case study serves as a compelling example of the tangible financial benefits and sustainable outcomes that can be realized through strategic investments in water filtration and recycling technologies offered by Filternox®.

2 Filternox® filters controlled by a PLC Control Panel.

| Application |

Sea water filtration prior to RO unit |

| Water Source |

Sea water |

| Filter Model | First stage: International Patented SPT-SBV-MR

Second stage: NTU Terminator SPT-MR |

| Filtration Level | First stage: 25 micron

Second stage: Deep filtration less than 5 micron |

| Flow |

15 m3/h / filter |

| Design Pressure / Working Pressure |

10 bar / 6 bar |

| Material: Filter Body / Element |

AISI 316L / AISI 316L |

| Filter Quantity | 2 |

1 Filternox® SPT-SBV-MR model filter controlled by a PLC Control Panel.

Filternox® internationally patented dual effect self cleaning SPT-SBV-MR model filter for Golf course irrigation water filtration in Romania.

| Application |

Golf course irrigation water filtration |

| Water Source |

Well water |

| Filter Model | International Patented SPT-SBV-MR |

| Filtration Level | 300 micron |

| Flow |

300 m3/h / Filter |

| Design Pressure / Working Pressure |

10 bar / 7,5 bar |

| Material: Filter Body / Element |

AISI 304L / AISI 316L |

| Filter Quantity | 1 |

4 Filternox® SPT-SBV-MR model filters are controlled by 1 PLC Control Panel.

Filternox® International Patented Dual Effect Self Cleaning Filters provide an advanced solution for Landscape Irrigation Filtration in Dubai, surpassing the capabilities of replaced filters. Experience uninterrupted, ultimate performance in treated sewage effluent filtration with Filternox®.

| Application |

Treated sewage effluent water filtration |

| Filter Model | International Patented SPT-SBV-MR |

| Filtration Level | 200 micron |

| Flow |

240 m3 /h/ Filter |

| Design Pressure |

16 bar |

| Material: Filter Body / Element |

AISI 316L / AISI 316L |

| Filter Quantity | 4 |

8 units of Filternox® PFH-MR model filters are controlled by 1 PLC Control Panel.

The photo was taken just a week ago, and it’s remarkable to see how the Filternox® Automatic Self-Cleaning Filters have been consistently operating flawlessly since the day they were first put into operation. Even after 11 years, they continue to perform at the same exceptional level as they did on the very first day.

| Application |

Cooling tower water filtration for compressor protection |

| Total flow |

1440 m3/h |

| Flow/Filter |

180 m3/h/ filter |

| Design Pressure |

PN10 |

| Filtration Level | 150 micron |

| Material: Filter Body / Element | AISI 304L / AISI 316L |

| Model | 4 units PFH 112608-MR (First order in 2012) 4 units PFH 116608-MR (Second order in 2014) |

| Filter Quantity | 8 |

| Cost of Consumables and Spare Parts | Only 5% of the filter investment cost in 11 years |

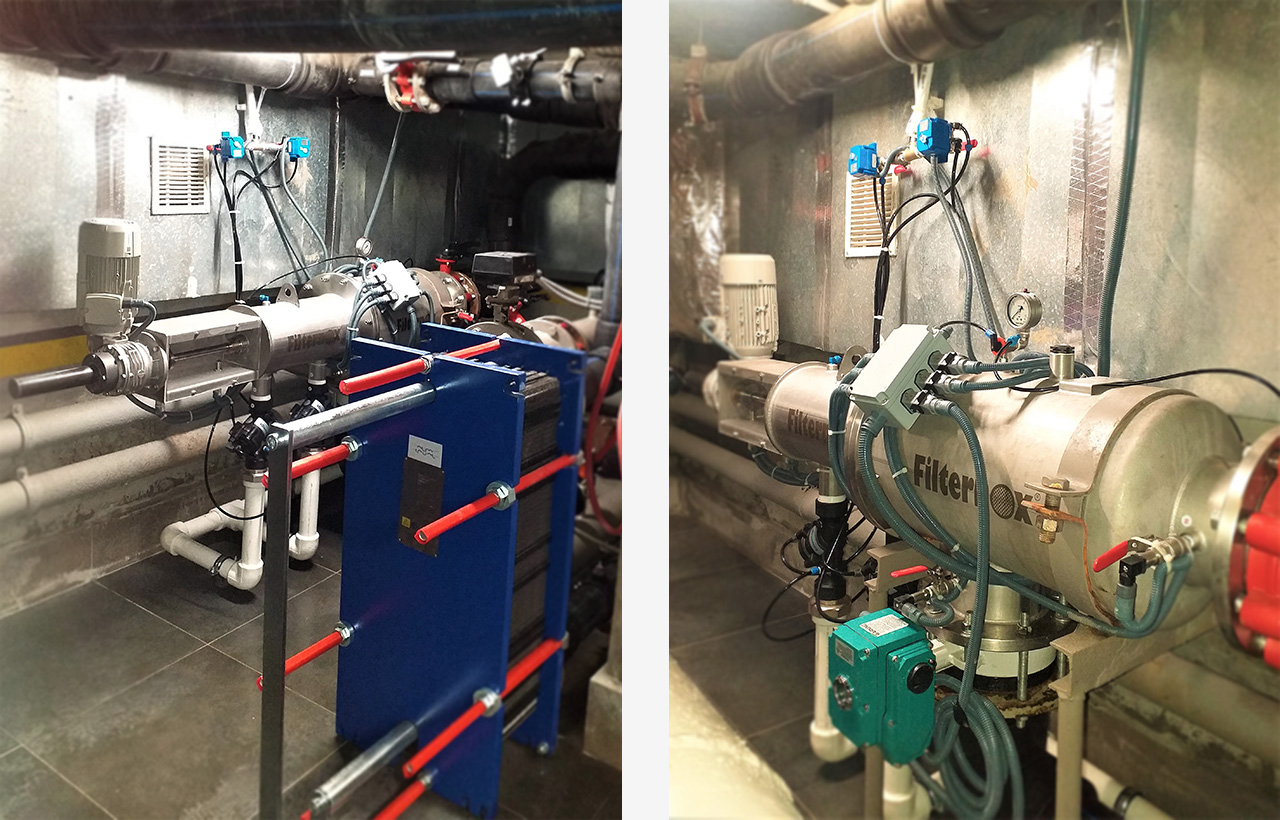

During the Factory Acceptance Test (FAT) conducted within Filternox®, general inspections of the filter, hydrostatic pressure tests and function tests were carried out in detail in collaboration with the end user. This procedure once again proves the quality and assurance of Filternox®.

2 Filternox® PFH 112610 model filters are controlled by 1 PLC Control Panel.

| Filter Model | PFH 112610 |

| Filtration Level | 100 micron |

| Pressure: Design / Test | 16 bar / 25 bar |

| Material: Filter Body / Element |

AISI 304L / AISI 316L |

| Filter Quantity | 6 |

| Location |

Bulgaria |

| Application |

Cooling Tower Filtration |

| Filter Model |

SPT-SBV 112506-MR |

| Design Pressure |

Max. 16 bar |

| Design Temperature | 60 °C |

| Filtration Level |

200 micron |

| Filter Body Material | AISI 304L Stainless steel |

| Filter Element Material |

AISI 316L Stainless steel |

| Flow Rate |

250 m³/h |

| Filter Quantity | 1 |

| Cleaning Mechanism |

Brush and Vacuum Nozzle (Double Effect) |

Our patented double-effect cleaning system delivers top-notch performance with a max design pressure of 16 bar, 60°C design temperature, and 200-micron filtration. Crafted from AISI 304L and AISI 316L stainless steel, it handles 250m³/h flow with a single unit. The Brush and Vacuum Nozzle cleaning mechanism reduces operational costs.

| Location |

Turkiye |

| Application 1 |

Process Water Filtration |

| Application 2 |

Cooling Water Filtration for Exchanger Protection |

| Filter Model 1 |

SPT 114406-MR |

| Filter Model 2 |

SPT-SBV 124616-MR |

| Design Pressure |

Max. 10 bar |

| Design Temperature | 60 °C |

| Filtration Level 1 |

100 micron |

| Filtration Level 2 |

250 micron |

| Filter Body Material | AISI 304L |

| Filter Element Material |

AISI 316L |

| Flow Rate 1 |

150 m³/h |

| Flow Rate 2 |

800 m³/h |

| Filter Quantity | 1+1 |

| Cleaning Mechanism 1 |

Vacuum Noozle |

| Cleaning Mechanism 2 |

Brush + Vacuum Nozzle (Double Effect) |

We’re thrilled to announce the successful start-up of our customer’s “Process Water Filtration” and “Cooling Water Filtration for Exchanger Protection” systems thanks to our patented double-effect cleaning system. With flow rates of 150 and 800 m3 per hour, and filtration levels at 100 and 250 microns, we’re redefining efficiency and excellence in water filtration.

| Location |

Turkiye |

| Application | Pump Suction Line Filtration |

| Filter Model |

BMF 132120 |

| Design Pressure |

Max. 6 bar |

| Design Temperature | 90 °C |

| Filtration Level |

10 mm |

| Filter Body Material | AISI 304L |

| Filter Element Material |

AISI 316L |

| Flow Rate |

2100 m³/h/filter |

| Filter Quantity | 2 |

| Cleaning Mechanism |

Manual |

The pump suction line filtration application serves not only to safeguard our pumps and equipment but is also crucial in maintaining their peak performance. Designed to operate flawlessly at 90°C with a 10mm filtration degree, our Filternox® filters have been tailored to meet the unique needs of our valued customers in the pulp and paper industry.

| Location |

Dubai |

| Application | Landscape & Irrigation System |

| Filter Model |

SPT-WBV 114306-MR (with elbow design) |

| Design Pressure |

Max. 16 bar |

| Design Temperature | 60 °C |

| Filtration Level |

100 micron |

| Filter Body Material | AISI 316L |

| Filter Element Material |

AISI 316L |

| Flow Rate |

140 m³/h/filter |

| Filter Quantity | 4 |

| Cleaning Mechanism |

Brush and Vacuum nozzle (Double Effect) |

| Location |

Turkey |

| Application | Rolling Mill Open Circuit Water Filtration |

| Filter Model |

SPT-SBV 120608-MR Skid Mounted Filtration System |

| Design Pressure |

Max. 10 bar |

| Design Temperature | 60 °C |

| Filtration Level | 100 micron |

| Filter Body Material | AISI 304L |

| Filter Screen Material | AISI 316L |

| Flow Rate |

200 m³/h/filter |

| Filter Quantity | 2 units (1 duty + 1 standby) |

| Cleaning System | Brush + Vacuum Nozzle (Double Effect) |

| Location |

Egypt |

| Application | Water Filtration Before UF |

| Filter Model |

PFH 118612-MR |

| Design Pressure |

Max. 10 bars |

| Design Temperature | 60 °C |

| Filtration Level | 300 micron |

| Filter Body Material | AISI 316L |

| Filter Screen Material | AISI 316L |

| Flow Rate |

500 m³/h/filter |

| Filter Quantity | 6 units |

| Cleaning System | Vacuum Nozzle |

| Location |

Egypt |

| Application | Filtration as a pretreatment step upstream of DAF and RO units |

| Filter Model |

SPT-WBV 112508-MR |

| Design Pressure |

Max. 10 bars |

| Design Temperature | 60 °C |

| Filtration Level | 2 mm |

| Filter Body Material | Duplex Stainless Steel |

| Filter Screen Material | Duplex Stainless Steel |

| Flow Rate |

335 m³/h/filter |

| Filter Quantity | 3 units |

| Cleaning System | Brush and Vacuum Nozzle (Double Effect) |

| Location |

Abu Dhabi, UAE |

| Application | Sea Water Filtration Before UF |

| Filter Model 1 | SPT-SBV 116408-MR (2 units) |

| Filter Model 2 |

SPT-WBV 114306-MR (1 unit) |

| Design Pressure |

Max. 10 bars |

| Design Temperature | 60 °C |

| Filtration Level | 100 microns |

| Filter Body Material | Super duplex |

| Filter Screen Material | Super duplex |

| Flow Rate 1 |

260 m³/h/filter (SPT-SBV 116408-MR) |

| Flow Rate 2 |

157 m³/h (SPT-WBV 114306-MR) |

| Filter Quantity | 2+1 = 3 units |

| Cleaning System | Brush and Vacuum Nozzle (Double Effect) |

| Location | Konya, Turkiye |

| Application | Coarse particle protection for the pump located after filter |

| Flow Rate | 344 m3/h |

| Design Pressure |

Max 10 bars |

| Design Temperature | 110 °C |

| Filtration Level | 6 mm (Perforated Wire) |

| Filter Body Material | AISI 304L |

| Filter Screen Material | AISI 316L |

| Filter Model | Special ACF 120508-MR (Skid System) with,

-Service Water Distribution Collector |

| Filter Quantity | 2 Sets (In 1 set: 1 duty+ 1 stand by, total: 4 pieces) |

| Cleaning System | Brush |

| Location | Silivri, Istanbul |

| Application | Garbage Storage Facility Leachate Water Filtration Before UF Membrane Filtration |

| Total Flow Rate | 1200 m3/h |

| Flow Rate | 300 m3/h/filter |

| Operating Pressure | 2,5 bar |

| Filtration Level | 800 micron |

| Filter Body Material | AISI 316L |

| Filter Screen Material | AISI 316L |

| Filter Model | SPT-SBV 116408-MR |

| Filter Quantity | 4 |

| Cleaning System | Brush + Vacuum Nozzle |

| Additional Info | Filtration system before discharging the garbage leachate water to the stream |

| Location | Istanbul |

| Application | Filtration For Wine Yard Drip Irrigation And Domestic Usage |

| Filtration Level | Deep filtration down to 5 micron |

| Filter Body Material | AISI 304L |

| Filter Screen Material | AISI 316L |

| Filter Model | NTU Terminator FMS-V 108101-MR |

| Filter Quantity | 1 |

| Cleaning System | Vacuum Nozzles |

| Location | Turkey |

| Application | Cooling Tower Water Filtration – Paper Mill |

| Flow Rate | 140 m3/h |

| Operating Pressure |

4 bars |

| Filtration Level | 150 microns |

| Filter Body Material | AISI 304L |

| Filter Screen Material | AISI 316L |

| Filter Model | SPT-SBV-MR |

| Filter Quantity | 1 |

| Cleaning System | Brush + Vacuum Nozzles |

| Location | Turkey |

| Application | Cooling Water Filtration for Heat Exchanger Protection in a Wood Processing Plant |

| Flow Rate | 250 m3/h |

| Operating Pressure |

Min. 5 bar |

| Filtration Level | 500 microns |

| Filter Body Material | AISI 304L |

| Filter Screen Material | AISI 316L |

| Filter Model | SPT-WBV-MR |

| Filter Quantity | 1 |

| Cleaning System | Brush + Vacuum Nozzles |

| Location | Turkey |

| Application | Cooling Water Filtration Prior to Heat Exchanger in an Aluminum Factory |

| Flow Rate | 300 m3/h |

| Operating Pressure |

3 bar |

| Design Temperature | 60°C |

| Filtration Level | Coarse Screen: 4 mm Fine Screen: 200 microns |

| Filter Body Material | AISI 304L |

| Filter Screen Material | AISI 316L |

| Filter Model | PFH-MR |

| Filter Quantity | 1 |

| Cleaning System | First Stage: Manual Second Stage: Vacuum Nozzles |

| Location | Hong Kong |

| Application | Sea Water Filtration |

| Flow Rate | Max. 2500 m3/h |

| Design Temperature | 60°C |

| Filtration Level | 6 mm |

| Filter Body Material | Duplex Stainless steel 1.4462 with internal epoxy coating |

| Filter Screen Material | Duplex Stainless steel 1.4462 |

| Filter Model | BMF |

| Filter Quantity | 2 |

| Cleaning System | Manual |

These specially designed Filternox® filters are made of Duplex stainless steel for sea water, cooling tower application. These filters are also fitted with zinc anode protection.

| Location | Italy |

| Application | UV protection |

| Flow rate |

40 – 45 m3/h |

| Operating pressure | 3 bar |

| Filtration level | 1000 microns |

| Design Temperature | 90°C |

| Body material | AISI 304L |

| Screen material |

AISI 316L |

| Cleaning system |

Brush + Vacuum Nozzles |

| Model |

FMS-PBV-MR |

| Quantity | 1 |

Filternox® patented filtration system produced for surface water filtration to protect UF.

| Location | Spain |

| Application | Sodium Carbonate Solution Filtration (17 % Na2CO3) |

| Flow rate |

3 m3/h |

| Operating pressure | 5 bar |

| Temperature |

90 °C |

| Filter Body Material | AISI 316L |

| Filter Screen Material | AISI 316Ti |

| First Stage Model | FMS-V 110102-MR |

| First Stage Filtration Level | 20 microns |

| Second Stage Model | NTU Terminator FMS-V-MR |

| Filter Quantity | 2 |

| Cleaning System | Vacuum Nozzles |

| Location | Norway |

| Application | UV protection |

| Flow rate |

80 m3/h |

| Operating pressure | 7 bar |

| Filtration level | 50 microns |

| Body material | AISI 304L |

| Screen material |

AISI 316L |

| Cleaning system |

Vacuum Nozzles |

| Model |

SPT-MR |

| Quantity | 1 |

Filternox® filtration system produced for aquaculture application. The filter has been working since 2016 to protect UV system.

| Location | Turkey |

| Application | Turbine bearings cooling water filtration |

| Flow rate |

100 m3/h |

| Design pressure | PN10 |

| Filtration level | 800 microns |

| Body material | AISI 304L |

| Screen material |

AISI 316L |

| Cleaning system |

Brushes and Vacuum Nozzles |

| Model |

SPT-SBV-MR |

| Quantity | 1 |

Filternox® patented filtration system produced to protect turbine bearings. Cooling water to be filtered comes directly from the river.

| Location | Samsun, Turkey |

| Application | Cooling water filtration for nozzle protection |

| Flow rate |

400 m3/h |

| Working pressure | 12 – 13 bar |

| Filtration level | 100 microns |

| Body material | AISI 304L |

| Screen material |

AISI 316L |

| Cleaning system |

Brushes and Vacuum Nozzles |

| Model |

SPT-SBV 120612-MR |

| Quantity | 2 |

| Additional equipment |

Drainage water recovery chamber |

| Location | Hong Kong |

| Application | Sea water filtration |

| Design pressure | PN10 – PN16 |

| Filtration level | 50 microns |

| Body material | AISI 316L |

| Screen material |

AISI 316L |

| Cleaning system |

Vacuum Nozzles |

| Model |

SFH-P |

| Quantity | 13 |

| Location | Trabzon, TURKEY |

| Application | Irrigation |

| Flow rate |

500 m3/h |

| Design pressure | PN10 |

| Filtration level | 130 microns |

| Body material | AISI 304L |

| Screen material |

AISI 316L |

| Cleaning system |

Brushes + Vacuum Nozzles |

| Model |

SPT-SBV-MR |

| Quantity | 1 |

Filternox® patented filtration system produced for filtration of open pond water for irrigation of 15,000 pomegranate, 220,000 walnut and 20,000 cherry trees.

| Location | Istanbul, TURKEY |

| Application | Leachate water filtration before UF |

| Flow rate |

300 m3/h /filter |

| Design pressure | PN10 |

| Filtration level | 800 microns |

| Body material | AISI 316L |

| Screen material |

AISI 316L |

| Cleaning system |

Brushes + Vacuum Nozzles |

| Model |

SPT-SBV-MR |

| Quantity | 4 units |

Filternox® patented filtration system produced for leachate water filtration for UV protection. The filters have HMI touch screen & e-remote RS communication functionality in addition to 7 dry contacts.

| Location | Mexico |

| Application | Heat exchanger protection |

| Flow rate |

130 m3/h |

| Design pressure | PN10 |

| Filtration level | 500 microns |

| Body material | AISI 316L |

| Screen material |

AISI 316L |

| Cleaning system |

Manual |

| Model |

YMF |

| Quantity | 6 |

| Location | Mauritius |

| Application | Water filtration for drinking water |

| Flow rate |

7-14 m3/h /filter |

| Design pressure | PN10 |

| Filtration level | 20 microns |

| Body material | AISI 304L |

| Screen material |

AISI 316L |

| Cleaning system |

Vacuum Nozzles |

| Model |

FMS 108102-MR |

| Quantity | 1 |

| Location | Brunei |

| Application | Filtration of municipality main water |

| Flow rate |

10 m3/h |

| Design pressure | PN10 |

| Filtration level | Down to 5 microns |

| Body material | AISI 304L |

| Screen material |

AISI 316L |

| Cleaning system |

Vacuum Nozzles |

| Model |

NTU Terminator FMS-V-MR |

| Quantity | 1 |

Filternox® automatic self-cleaning filter is going to be installed on municipal main line and it has a special screen, capable of filtration down to 5 micron which is able to reduce TSS and NTU in the water.

| Location | Belgium |

| Application | River water filtration |

| Design pressure | PN10 |

| Filtration level | 100 microns |

| Body material | AISI 316L |

| Screen material |

AISI 316L |

| Cleaning system |

Double effect, Brushes + Vacuum Nozzles |

| Model |

FMS-SBV-MR |

| Quantity | 2 units |

Filternox® patented filtration system produced for river water filtration. The filters have HMI touch screen & e-remote RS communication functionality in addition to 7 dry contacts.

| Location | Norway |

| Application | Cooling water filtration |

| Flow rate |

9 m³/h |

| Working pressure | 7 bar |

| Filtration level | Down to 1 micron |

| Body material | AISI 304L |

| Filter screen material |

AISI 316L |

| Cleaning system |

Double effect, Brushes + Vacuum Nozzles |

| Model |

FMS-SBV-MR |

| Quantity | 2 units, serially connected |

Filternox® patented filtration system produced for recycling water. The filtration rate is down to 1 micron to protect the process. The filters are designed to be controlled by one control panel and special safety for drainage line.

| Location | Bursa, TURKEY |

| Application | Cooling tower, side stream filtration |

| Design Pressure | 10 bar |

| Filtration level | 50 microns |

| Body material | AISI 304L |

| Filter element material |

AISI 316L |

| Cleaning system |

Brushes & Vacuum nozzles |

| Model |

SPT-WBV 114304-MR |

| Quantity | 1 unit |

Filternox® YMF has a wide range of applications to filter particles in the water.

| Body Material | Max. Operating Temperature | Max. Operating Pressure |

|---|---|---|

| AISI 304L, AISI 316L | 90°C | PN10 / PN16 |

| Screen Material | ||

| AISI 316L |

For different pressure and material requirements, please contact us.

| Location | Adana, Turkey |

| Application | TSE pond water filtration for golf course irrigation system protection |

| Flow rate |

400 m³/h /filter |

| Operating Pressure | 7 bar |

| Filtration level | 250 microns |

| Body material | AISI 304L |

| Filter screen material |

AISI 316L |

| Cleaning system |

Patented double effect, Brushes + Vacuum Nozzles |

| Model |

SPT-SBV-MR |

| Quantity | 1 unit |

Filternox® patented double cleaning mechanism filtration system produced for the irrigation of the golf course in Incirlik US Air Base in Adana, Turkey.

| Location | Kocaeli, Turkey |

| Application | Cooling water filtration |

| Flow rate |

10 m³/h |

| Design Pressure | PN10 |

| Filtration level | Down to 10 microns (Composite Screen) |

| Body material | AISI 304L |

| Filter screen material |

AISI 316L |

| Cleaning system |

Double effect, Brushes + Vacuum Nozzles |

| Model |

NTU Terminator FMS-V-MR |

| Quantity | 2 units, 1 per line |

Filternox® filtration system produced to remove suspended solids & turbidity of the cooling water. NTU Terminator FMSL-V 110102-MR has PLC control panel & fully automatic filtration system with e-remote RS communication functionality.

Filternox® NTU Terminator filtration system produced and commissioned for the facility of our client, one of the leading companies in Turkey and Europe in the field of cement production, located in Kocaeli.

| Location | Kocaeli, TURKEY |

| Application | River water filtration |

| Flow | 100 m3/h / filter |

| Filtration level | Up to 5 microns |

| Body material | AISI 304L |

| Filter element material |

AISI 316L |

| Inlet-outlet diameter | 6″ (DN150) |

| Quantity | 2 units |

| INLET | OUTLET | DRAINAGE | |

| TSS (ppm) | 110 | 71 | >750 |

| Turbidity (NTU) | 155 | 92 | >1000 |

Filternox® filtration system, produced and commissioned to filter sea water for one of the leading hotel companies in the world.

| Location | Istanbul, Turkey |

| Application | Sea water filtration before heat exchangers |

| Design Pressure | PN10 |

| Filtration level | 300 microns |

| Body material | AISI 316L |

| Filter screen material |

AISI 316Ti |

| Cleaning system |

Double effect, Brushes + Vacuum Nozzles |

| Model |

SPT-WBV-MR |

| Quantity | 1 unit |

| Location | Kocaeli, TURKEY |

| Application | Cooling tower side stream filtration for oil refinery |

| Flow | 350 m3/h / filter |

| Pressure |

10 bar |

| Filtration level | 100 microns |

| Filter body material | AISI 304L |

| Filter element material |

AISI 316L |

| Model |

SPT-SBV-MR |

| Quantity | 2 units |

| Cleaning system |

Patented double effect ( brushes + nozzles) |

| Control System | PLC Control Panel, fully automatic filtration system with e-remote RS communication functionality |

| Protection Class | Ex-Proof Zone 2 |

The filters in use were replaced with advanced tech Filternox SPT-WBV-MR filters for increased efficiency and reliability.

| Location | Rize, TURKEY |

| Application | HPP cooling water filtration |

| Flow | 180 m3/h / filter |

| Pressure |

10 bar |

| Filtration level | 800 microns |

| Filter body material | AISI 304L |

| Filter element material |

AISI 316L |

| Model |

SPT-WBV-MR |

| Quantity | 2 units (1 duty + 1 standby) |

| Cleaning system |

Patented double effect ( brushes + nozzles) |

| Control System | PLC Control Panel, fully automatic filtration system with e-remote RS communication functionality |

Filternox® Automatic Self-Cleaning Filters perform successfully in many applications.