Before we begin presenting our Filters for Fish Farm Water Treatment Systems, we would like to answer some frequently asked questions.

| Can you ship to Middle-East? | We are shipping Filternox® filters at least once a week to countries in the Middle-East region including:

Qatar, United Arab Emirates, Jordan, Lebanon, Egypt, Iran, Oman, Yemen and Bahrain. |

| Can it withstand harsh atmospheric conditions like excessive heat, sand storms or moisture? How about high salinity? |

Our filters are trusted by many global brands and can keep working flawlessly with certified UV and IP resistances. We can build filters with super-duplex materials for extremely salty sea water and brackish fossil aquifers. |

| Are you able to provide maintenance service? | Our filters do not require frequent maintenance, however we are able to provide service personnel worldwide. |

Fish farms use either sea water or fresh water as a source of water for fish production. Because of the requirement of sufficient fresh water, a water purification system must be integrated in the fish farm.

As well as the supply water being filtered, the water inside the tanks and basins should also be continuously filtered by side stream to maintain the necessary sanitary water conditions.

The complete stainless steel structure of Filternox® automatic self cleaning strainers provide the most convenient and hygienic treatment for the removal of suspended solids and particles for aquafarming with minimal maintenance costs.

Contact us today for a customized aquafarming water purification solution. No matter how big or small your project might be, Filternox® engineers are going to assist you from start to finish.

Before we begin presenting our Filters for Surface Water Treatment Systems, we would like to answer some frequently asked questions.

| Can you ship to Middle-East? | We are shipping Filternox® filters at least once a week to countries in the Middle-East region including:

Qatar, United Arab Emirates, Jordan, Lebanon, Egypt, Iran, Oman, Yemen and Bahrain. |

| Can it withstand harsh atmospheric conditions like excessive heat, sand storms or moisture? How about high salinity? |

Our filters are trusted by many global brands and can keep working flawlessly with certified UV and IP resistances. We can build filters with super-duplex materials for extremely salty sea water and brackish fossil aquifers. |

| Are you able to provide maintenance service? | Our filters do not require frequent maintenance, however we are able to provide service personnel worldwide. |

Like sea water, surface water also contains a wide variety and sizes of contaminant particles. To effectively meet this challenge, filtration units require both coarse and fine automatic filtration. Sediment build up and the consequent loss of efficiency is one of the main problems in heat exchangers, nozzles, ion exchange systems, seals, membranes and other sensitive equipment.

To prevent unscheduled and unforseen system shut downs for cleaning, the installation of Filternox® Automatic Self Cleaning Filters will remove suspended particles from the incoming water source such as lake water and river water, thus providing uninterrupted operating conditions.

The use of Filternox® Automatic Self Cleaning Filters helps maintain optimum pumping conditions by preventing pressure drop caused by sediment build up.

Filternox recently designed an enhanced new filter model especially for surface water treatment applications.

Contact us today for a customized lake or river water filtration solution. No matter how big or small your project might be, Filternox® engineers are going to assist you from start to finish.

Before we begin presenting our sea water filters, we would like to answer some frequently asked questions.

| Can you ship to Middle-East? | We are shipping Filternox® filters at least once a week to countries in the Middle-East region including:

Qatar, United Arab Emirates, Jordan, Lebanon, Egypt, Iran, Oman, Yemen and Bahrain. |

| Can it withstand harsh atmospheric conditions like excessive heat, sand storms or moisture? How about high salinity? |

Our filters are trusted by many global brands and can keep working flawlessly with certified UV and IP resistances. We can build filters with super-duplex materials for extremely salty sea water and brackish fossil aquifers. |

| Why do I need to filter sea water? | Organic and inorganic TSS, algae, sea species. |

| Are you able to provide maintenance service? | Our filters do not require frequent maintenance, however we are able to provide service personnel worldwide. |

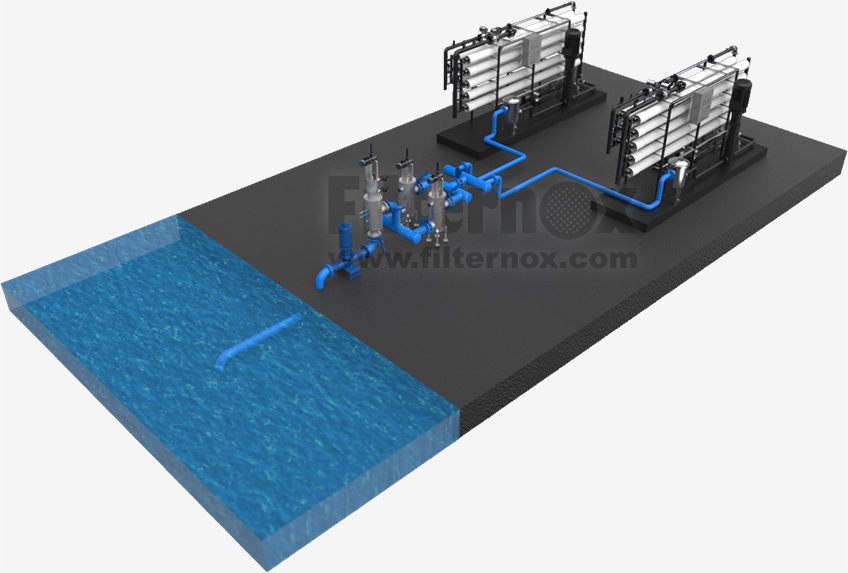

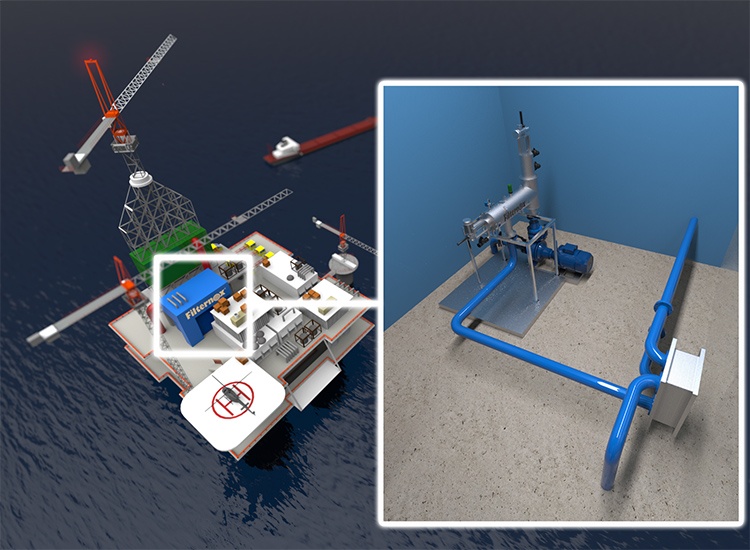

The size of dirt particles contained in sea water varies widely. Therefore sea water filtration needs more care than other fluids. A very special filtration solution is required to remove particles from 10 mm at one end of the spectrum down to 50 micron particles at the other. It requires filtration of both coarse and fine particles at the same time.

Filternox® offers special models, KFH, KTW and KQR which have both coarse and fine filtration stages in one body and both featuring an independent automatic self-cleaning system.

Filternox® automatic self cleaning filters are used for sea water filtration on oil platforms, the protection of heat exchangers, ultra filtration and Reverse Osmosis units as well as recreational uses.

Another important consideration in the filtration of sea water is the corrosive effect it has. Filternox® offers the best permanent solution with a rubber coating over its stainless steel body.

Contact us today for a customized sea water filtration solution. No matter how big or small your project might be, Filternox® engineers are going to assist you from start to finish.

Before we begin presenting our Filters for Well Water Filtration Systems, we would like to answer some frequently asked questions.

| Can you ship to Middle-East? | We are shipping Filternox® filters at least once a week to countries in the Middle-East region including:

Qatar, United Arab Emirates, Jordan, Lebanon, Egypt, Iran, Oman, Yemen and Bahrain. |

| Can it withstand harsh atmospheric conditions like excessive heat, sand storms or moisture? How about high salinity? |

Our filters are trusted by many global brands and can keep working flawlessly with certified UV and IP resistances. We can build filters with super-duplex materials for extremely salty sea water and brackish fossil aquifers. |

| Are you able to provide maintenance service? | Our filters do not require frequent maintenance, however we are able to provide service personnel worldwide. |

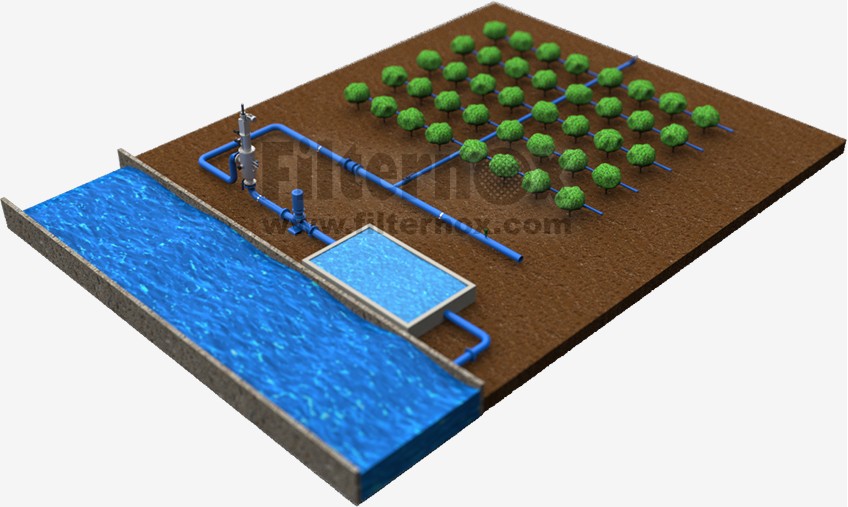

Reduction of available fresh water sources has become a major problem in recent years. The consequent reduction in water volume has also increased the concentration of contaminants and pollution. Because of this problem, modern irrigation systems, using either underground or surface water are requiring more efficient filtration systems.

Automatic irrigation filters protect irrigation and fertilizing systems from all kinds of particles and assure years of continued operation without letting drippers and sprinkler nozzles clog by suspended solids such as algae, sand, leaves, molluscs, etc.

Filternox® auto clean filters are the perfect solution for golf courses, agriculture, gardening and all applications wherever water economy and flawless operation is required.

Automatic backflush filters offer a special hydraulic control system which triggers the back-flush without requiring any extra energy other than the pressure of water. Also during the back flush, there is no interruption of water flow with this hydraulic control system.

We produce double stage automatic self-cleaning models to be implemented directly to the surface water ahead of the irrigation system which require no additional investment.

Contact us today for a customized water purification solution for irrigation systems. No matter how big or small your project might be:

A single filter unit for your hobby garden or hundred for industrial level filtration.

Filternox® engineers are going to assist you from start to finish.

Before we begin presenting our Filters for HVAC & Cooling Tower Water Treatment Systems, we would like to answer some frequently asked questions.

| Can you ship to Middle-East? | We are shipping Filternox® filters at least once a week to countries in the Middle-East region including:

Qatar, United Arab Emirates, Jordan, Lebanon, Egypt, Iran, Oman, Yemen and Bahrain. |

| Can it withstand harsh atmospheric conditions like excessive heat, sand storms or moisture? How about high salinity? |

Our filters are trusted by many global brands and can keep working flawlessly with certified UV and IP resistances. We can build filters with super-duplex materials for extremely salty sea water and brackish fossil aquifers. |

| Are you able to provide maintenance service? | Our filters do not require frequent maintenance, however we are able to provide service personnel worldwide. |

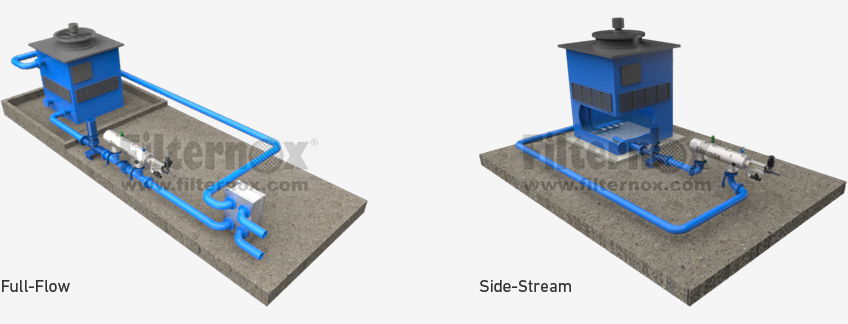

Cooling towers act in a similar way to air scrubbers by collecting all particles from the surrounding environment into the cooling water. These particles, such as dust, sand, algaes and pollen easily attach to hot surfaces during circulation inside the cooling system and cause clogging, fouling and reduction in efficiency of the process, which results in the shut down of the system for cleaning. Efficient filtration is very important for maintaining the continuous operation of the cooling system.

By using Filternox® filters in your HVAC (Heating, Ventilating and Air Conditioning) or cooling tower water treatment systems, either as sidestream or full flow applications, you will avoid all of these problems.

By filtering the cooling water, you will also decrease chemical material consumption for water conditioning. (chlorine, biocides, algaecides, etc.)

Contact us today for a customized HVAC & cooling tower water treatment solution. No matter how big or small your project might be, Filternox® engineers are going to assist you from start to finish.

Before we begin presenting our Filters for Hydro Power Generation Systems, we would like to answer some frequently asked questions.

| Can you ship to Middle-East? | We are shipping Filternox® filters at least once a week to countries in the Middle-East region including:

Qatar, United Arab Emirates, Jordan, Lebanon, Egypt, Iran, Oman, Yemen and Bahrain. |

| Can it withstand harsh atmospheric conditions like excessive heat, sand storms or moisture? How about high salinity? |

Our filters are trusted by many global brands and can keep working flawlessly with certified UV and IP resistances. We can build filters with super-duplex materials for extremely salty sea water and brackish fossil aquifers. |

| Are you able to provide maintenance service? | Our filters do not require frequent maintenance, however we are able to provide service personnel worldwide. |

A decrease in efficiency due to the accumulation of particles is one of the main problems with heat exchangers. Even a minor layer of scale causes a dramatic decrease in the transfer of heat which can result in the unforeseen shut down of the system for cleaning.

Filternox® automatic self cleaning filters, by removing all suspended solids and particles, provide uninterrupted working conditions for heat exchangers.

As well as protecting heat exchangers, Filternox® automatic self cleaning filters will also provide protection for nozzles, ion exchangers, seals, membranes and other sensitive equipment installed in your system.

The use of Filternox® automatic self cleaning filters help maintain optimum pumping conditions through the prevention of pressure drop caused by sediment build up.

Dam water used for the cooling of the turbine bearing and sealing equipment of the hydroelectric power plants, contains different sizes of particles as all the surface waters creating fouling in the pipes and heat exchanging surfaces and damaging the turbine bearings and seals.

The continuous operation of the turbines has vital importance for the hydroelectric power plants.

Filternox® automatic self-cleaning strainers provide a solution to this filtration problem with two stage filtration models, which offer a convenient and cost effective way to address water treatment challenges in hydroelectric power plants, extending the life of bearings and seals equipment and reducing maintenance and operating costs.

Contact us today for a customized power plant water filtration solution. No matter how big or small your project might be, Filternox® engineers are going to assist you from start to finish.

Clean water has become a major problem since water usage has increased with the increasing population and the development of the industries. Water shortage brings people to seek for alternative water sources for irrigation.

The problem is: “How do municipalities, especially the municipalities in the Middle East, continue to irrigate green fields? How are they going to build new green zones? How are we going to maintain recreational areas such lawns and gardens?”

The answer is to reuse wastewater! Especially in the Middle East, water shortage has led people to use treated sewage effluent (TSE) as a water source for landscaping. With wastewater recovery, it is possible to supply the amount of water used in landscaping. In this case, filtration and disinfection become important together with a properly operating water treatment plant.

At this moment Filternox® Filters are on the scene.

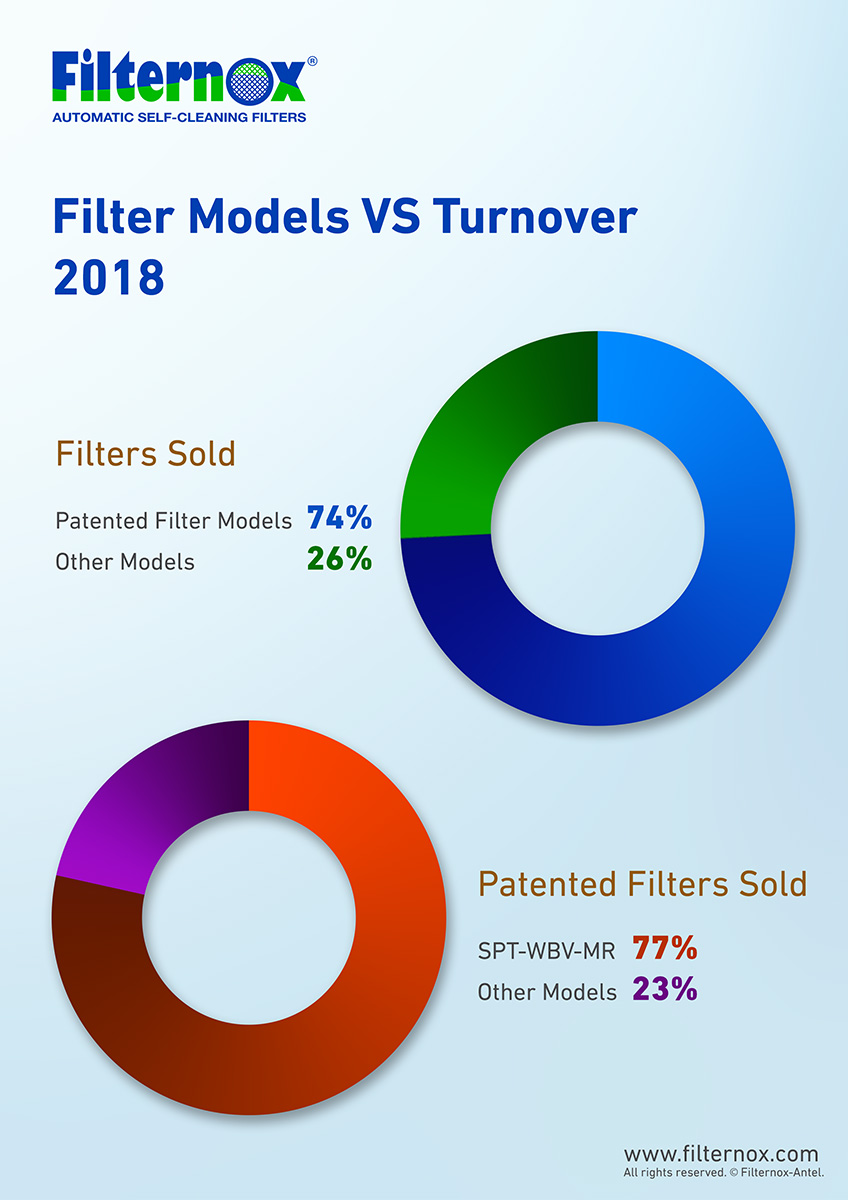

As Filternox® we are involved in many landscaping & irrigation projects worldwide and specifically, we have many filtration applications which were held by UAE. Depending on the water quality, Filternox® recommends its high technology SPT-WBV-MR filters which can handle high dirt loads.

Patented technology SPT-WBV-MR filters have many advantages for the municipalities such as;

One of the most important features of Filternox® Filters is that they are non-clog type. In order to test this characteristic and prove it, our double cleaning technology filter has been challenged with the “Shanghai Test” in Holland. During this test, our filter with a filtration level of 20 microns has faced with 2000 ppm (suspended solids) artificial mud and eventually it continued its normal operation after each back-flush.

Municipal maintenance directors, consultants, and contractors are welcome to contact us and let us begin solving their problems to reduce maintenance costs together. With our more than 30 years of expertise in the field, we are ready to make tailor made designs for your applications with no extra cost.

Below photos show the difference between before and after Filternox® Filter applications. The irrigation system protection was improved dramatically and can be clearly seen on landscaping greenery area.

Filternox® patented technology SPT-WBV-MR model filters have been supplied for Veolia for the project of raw well water filtration in a Water Treatment Plant, Serbia. The filters have been provided with custom design according to project requirement with complete stainless steel structure, with its PLC electric control panel and electric actuated outlet valves.

| Application Area |

Water Treatment Plant |

| Application | Filtration of Raw Well Water |

| Filtration Flow Rate |

320 m3/h /filter |

| Filtration Level |

100 micron |

| Filter Model | SPT-WBV 122412-MR |

| Inlet-Outlet Diameter |

DN 300 |

| Filter Quantity |

2 |

| Location | Turkey |

| Water Source | Dam water |

| Application | Agricultural irrigation (DSI) |

| Filtration System Flow Rate | 2480 m3/h |

| Filter Type | Double Effect Cleaning Mechanism(Brush&Vacuum Nozzle) Automatic Self-Cleaning Filter |

| Filter Model | SPT-WBV 120514-MR |

| Number of filter units | 6 |

| Filtration Level | 200 micron |

| Body material | AISI 304L |

| Screen material | AISI 316Ti |

| Location | Turkey |

| Factory | Dense Soda Ash and Sodium Bicarbonate factory |

| Application | Filtration of trona ore hot water solution |

| Filter Model | Filternox® SPT 120408-MR |

| Number of filter units | 16 units |

| Filtration Level | 25 micron |

| Screen area / filter | 10.800 cm² / filter |

| Body material | AISI 304L |

| Screen material | AISI 316L |

The Solution Mining Research Institute (SMRI) defines solution mining as “mining of underground, water-soluble minerals, usually using one or more drilled wells to dissolve the minerals with water”. Minerals such as salt, potash, trona, and magnesium salts may be produced by pumping saturated fluid from underground caverns. The caverns are created by pumping out the saturated ‘brine’ while pumping in fresh water as a controlled production process. The minerals are then recovered from the saturated fluid by recrystallization.

Filternox® played a big role in the second biggest trona reserve in the world. Trona reserves are meant to be dissolved with hot water injection by production wells, which then forms trona solution (brine). This mining facility provides the trona solution (brine) which is the raw material of the process plant.

The trona (sodium sesquicarbonate Na2CO3 NaHCO32H2O) is mined by solution mining, a safe and environmentally friendly mining technique. The trona solution, i.e., brine which is subjected to monohydrate process in the production lines of process unit is converted into Dense Soda Ash and Sodium Bicarbonate products, and 2.5 million tons of Dense Soda Ash and 200,000 tons of Sodium Bicarbonate is produced annually.

Dense soda ash produced from trona at the plant is used in a wide range of industrial areas such as glass industry, paper production, and detergent production. Sodium Carbonate is a basic salt. Its aqueous solution is clear and colourless, and its chemical formula is Na2CO3.

In the solution pretreatment unit, suspended solids are removed from brine, which come from the mining wells. The suspended solids are removed with Filternox® filters. 16 units of Filternox® filters remove particles down to 25 micron. After the whole filtration process, the filtrated brine is stored in the raw brine tanks.

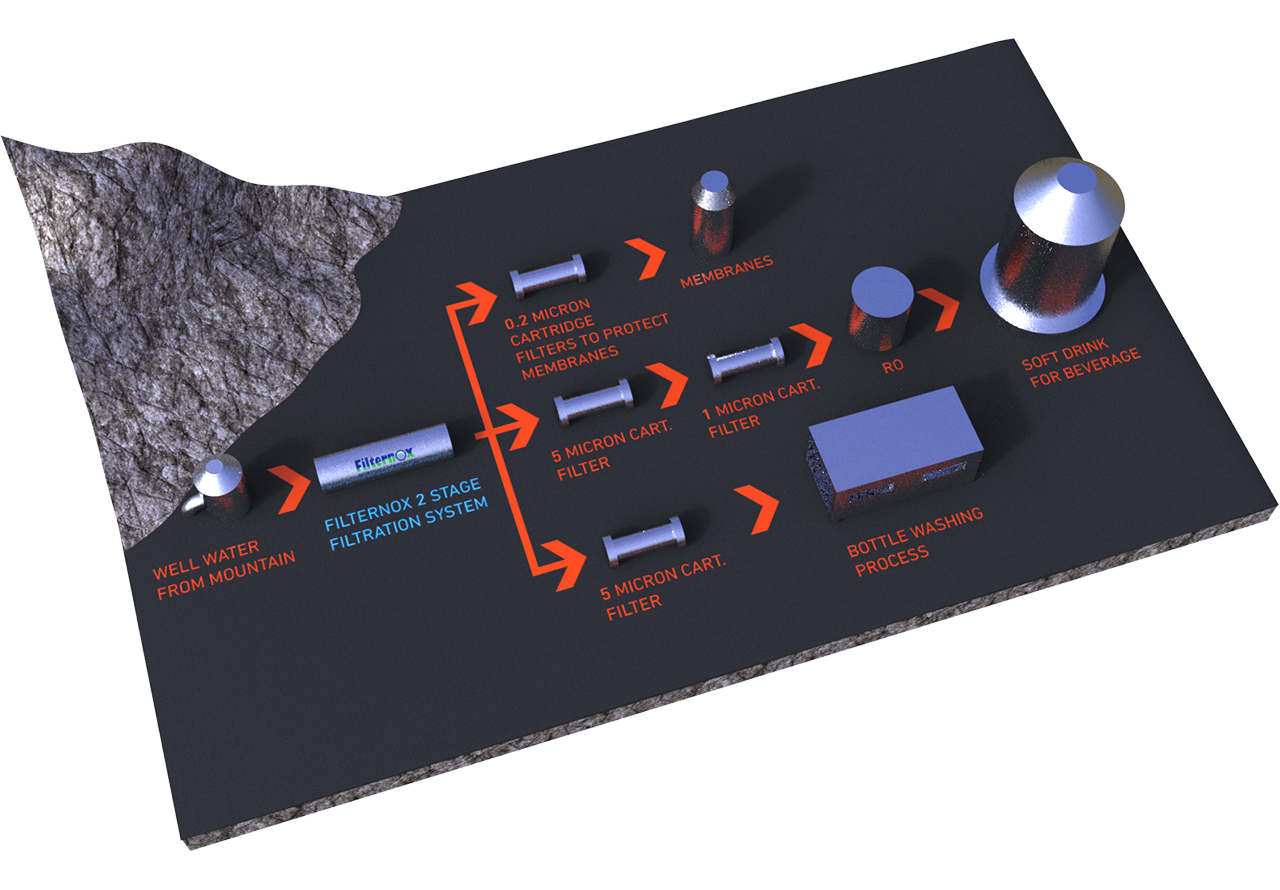

| Project | Food and Beverage Industry / Venice – Italy (Largest water bottling factory in Italy) |

| Application |

Filtration of well water from the mountain |

| Filternox® Supplied System | 1 unit Filternox® SPT-WBV 116408-MR model filter as first stage filtration and 2 units Special SPT 124408-MR model filters as second stage filtration. PLC electric control panel and auxiliary equipment. |

| Filtration System Flow | 200 m³/h |

| First Stage Filtration Level | 80 micron |

| Second Stage Filtration Level | 20 micron |

| First Stage Filter Filtration Area |

7.800 cm² |

| Second Stage Filters Total Filtration Area | 25.600 cm² |

| Filter Body Material | AISI 304L |

| Filter Element Material | AISI 316L |

| Filter Model | SPT-WBV 114306-MR |

| Treated Capacity | 110 m3/h |

| Filtration Level | 500 micron |

| Quantity | 2 units |

| Application | Tertiary waste water recycle system in a chemical plant |

| Project | Hospital in Istanbul / Turkey |

| Application | Sweeper Basin Pipe System Water Filtration of Cooling Tower via Filternox® Skid Mounted System |

| Filternox® Supplied System | Ready to install Filternox® Skid Mounted System including Filternox® SPT 116508-MR model filter, high capacity pump, PLC electric control panel, and auxiliary equipment |

| Control & Automation | One unit PLC electric control panel controls whole skid mounted system; Filternox® self cleaning filter and pump |

| Flow | 320 m3/h / Filternox® skid mounted system |

| Filtration level | 100 micron |

| No of skid mounted systems | 4 units |

| Pump motor power | 37 kW |

| Screen surface area | 10.000 cm2/filter |

| Filter housing & skid structure material | AISI 304L |

| Filter screen material | AISI 316L |

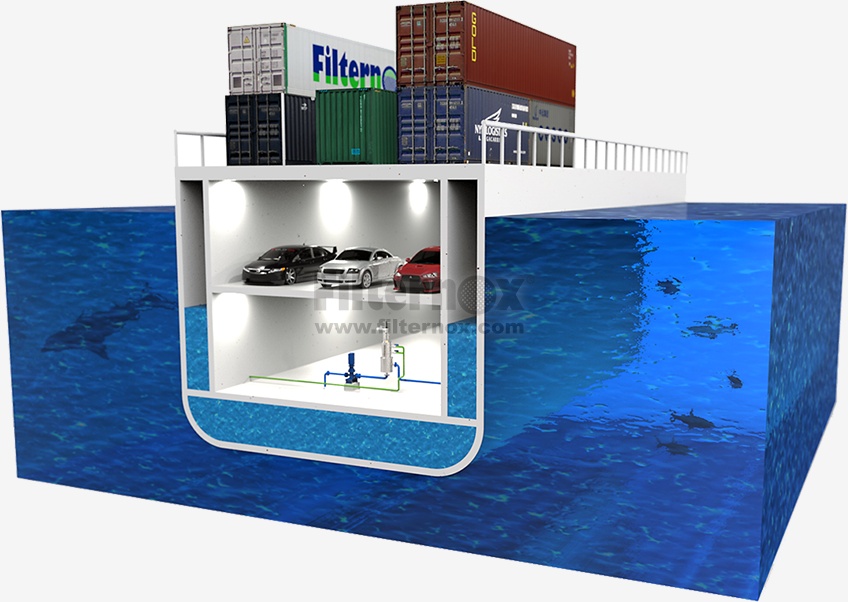

New regulations require for almost all types of vessels to implement filtration systems of maximum 50 microns followed by a UV system for disinfection of ballast water. Filternox® engineers developed a new model designed specifically for ballast water treatment.

As the ballast system requires high flows, and to meet the 50 micron filtration requirement, filtration surface areas have to be large. The technology used in Filternox® ballast water treatment systems provide the optimum surface area for efficient filtration.

Filternox® also offers models that combine two stage filtration within one unit with automatic self-cleaning of the coarse screen structure integrated into the fine screen body, making it ideal for management of ballast water.

For a more complete and safer ballast water filtration system, Filternox® can also implement the BMF-TW filter to eliminate larger particles and protect the pump.

| Location | Turkey |

| Plant | Integrated Health Campus |

| Application | Cooling Tower Side Stream Filtration |

| Flow | 18 m³/h / skid mounted filtration system |

| Filter Model | Filternox® FMS-V 108102-MR |

| Amount of skid system | 2 units |

| Filtration Level | 50 micron |

| Screen area / filter | 1.250 cm² |

| Body material | AISI 304L |

| Screen material | AISI 316L |

| Location: | Spain – Coruna |

| Factory: | Repsol |

| Application: | Heat exchanger protection by filtration |

| Total Flow | 10 m³/h |

| Filter Model | Filternox® FMS-V 108102-MR |

| Amount of filter units | 1 unit |

| Filtration Level | 25 micron |

| Screen area | 1.250 cm² |

| Body material | AISI 304L |

| Screen material | AISI 316L |

REPSOL® is a registered trademark of REPSOL, S.A.

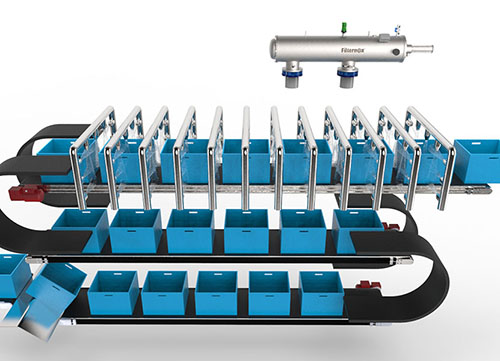

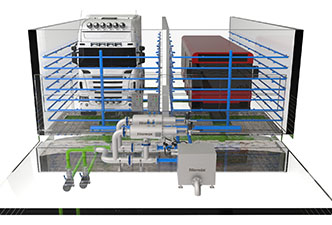

Filternox® filters are successfully integrated in reusable container(tray, crate, trolley, pallet, bin, etc.) washers and extend the life of such cleaning and disinfection systems by protecting nozzles from blockage caused by dirt and many types of contaminants.

Filternox® filters are successfully integrated in reusable container(tray, crate, trolley, pallet, bin, etc.) washers and extend the life of such cleaning and disinfection systems by protecting nozzles from blockage caused by dirt and many types of contaminants.

Protecting your washer equipment helps you ensure longer up-times and prevents unscheduled system down-times.

Filternox® SPT-WBV-MR and PFH-MR automatic self-cleaning filters are our recommended products for washing & re-circulation installations and both models can be easily adapted to any type of industrial washer system.

Industrial crate washer, protected by Filternox® automatic self-cleaning filters.

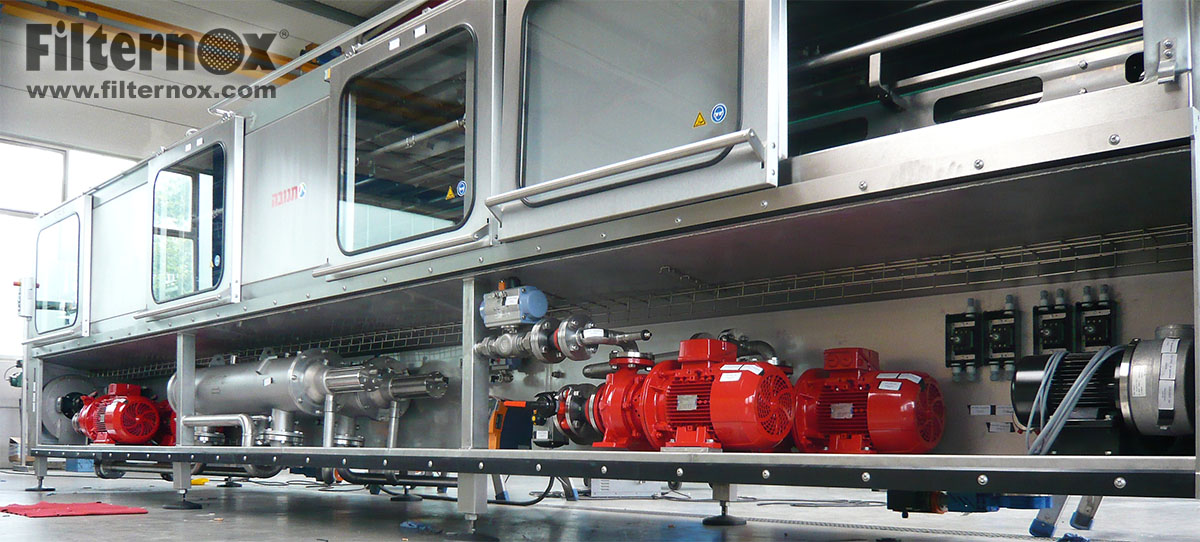

Filternox® filters are widely used in the automotive industry as well as in different processes and units of many industrial plants such as iron and steel, paper, textile, plastic and chemistry.

Filternox® filters are widely used in the automotive industry as well as in different processes and units of many industrial plants such as iron and steel, paper, textile, plastic and chemistry.

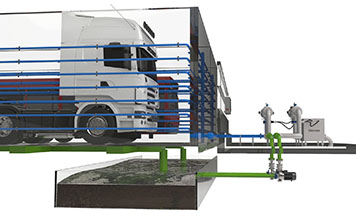

Automatic Self-Cleaning filters are preferred for water recovery and spray nozzle clogging prevention in the sprinkler system where the vehicles are tested for leakages.

The vehicles are contaminated with sand, gravel, silt and other pollutants during the various tests carried out at open-air environment after their production. Following these tests, the vehicles are subjected to a leakage test. For that, the water sprayed on the vehicle is contaminated with pollutants on it and collected in a pool. The water in the pool is fed back to the sprinkler system to provide a continuous circulation.

The vehicles are contaminated with sand, gravel, silt and other pollutants during the various tests carried out at open-air environment after their production. Following these tests, the vehicles are subjected to a leakage test. For that, the water sprayed on the vehicle is contaminated with pollutants on it and collected in a pool. The water in the pool is fed back to the sprinkler system to provide a continuous circulation.

These types of contaminants and particles must be removed before they pass to the water sprinkler system in order to prevent clogging at the spray nozzles and also to prevent scratching on the vehicle paint and make the test more efficient.

Filternox® SPT-WBV-MR model filtration system has a patented design that enables effective filtration of water containing coarse and fine particles. SPT-WBV-MR, which has a double-effect cleaning system with brush and vacuum nozzle, is automatically cleaned from coarse particles on the surface of the screen by brush and then fine particles from the surface of the screen by vacuum nozzle. cleaning.

Filternox® provides efficient and easy-to-use solutions in the fields of Heat Exchanger Cooling Water and Sea Water Filtration.

Contaminants in your cooling water cause heat exchangers to get blocked. In this case, filtration is very important because this blockage will cause problems in your system by preventing cooling (heat transfer) at the desired level.

Filternox® filters filter both coarse and fine particles in your water and prevent clogging problems in the heat exchangers. In this way, you will increase your operating efficiency and reduce your operating and maintenance costs.

Filternox® filters save water by reducing the amount of waste water you discharge. Thus it reduces your operating costs and enabling you to have a more environmentally friendly system.

Filternox® filter models suggested for sea water filtration in oil refinery applications have special technology that can perform filtration for both coarse and fine particles in the same filter body. The filters have a double effect cleaning mechanism.(see video) In the first stage cleaning, coarse particles are removed from the drain by sweeping the surface of the screen with the aid of a brush. The second stage cleaning is realized just right after the brush cleaning which fine particles on the screen surface are sucked out of the drain by the help of a vacuum nozzle. The backflush drainage of the brush and nozzle systems are independent from each other. This cleaning process will be selected in two stages or three stages depending on your system pollution.

Contact us today for a customized filtration solution.

In recent years, water has become the biggest global concern due to depletion of water sources and global warming. This issue led people to find alternative solutions to preserve water sources and make benefit from water as much as possible. To reduce the domestic waste water discharged, new approaches have revealed. These new approaches aim to reevaluate domestic waste water by separating streams at the source with stream segregation as black water and greywater. Black water which can be basically defined as toilet wastewater and greywater is any domestic wastewater but toilet wastewater.

In conventional wastewater management systems, domestic wastewater is collected by a sewer system which mixes less polluted wastewater with the high polluted. This is ending up large investments on both drinking water supply and wastewater treatment systems. In recent years, domestic wastewater has been accepted as a source to be reevaluated.

Greywater is composed of anything (wash basins, bathtubs, laundry and kitchen sinks) but the toilet wastewater. Greywater is rich in organic matter but less polluted than black water. Greywater can be reused for cleaning, irrigation, toilet flushing and car washing.

Considering the amount of black water and greywater, 75% of domestic wastewater is composed of greywater.

Since greywater has no remarkable pollution and has no toilet wastewater inside, it has less amounts of pathogens and low concentrations of nitrogen and phosphorous. Hence, the treatment and the reuse of greywater are easier to apply and cost-friendly.

Filternox® filters play a big role in Greywater Applications to remove solid particles like hair, dust, sand, mud and other suspended solids for various applications. For example in drip irrigation systems, tubing has very small drippers. These drippers get clogged very quickly by particles in greywater. In order to achieve a great success in greywater use, drip irrigation filtration is required to prevent clogging of outlets. Filternox® Automatic Self-Cleaning Filters provide solution in this case by removing these solid particles and prolong drip irrigation system’s life.

Another example, in car washing, it is needed to get rid of the solid particles in the greywater.

Otherwise these particles scratch the car paint and cause damage on the car surface. Car washing companies prefer Filternox® Self-Cleaning Filters to avoid any damage to their clients’ cars.

In domestic greywater use like toilet flushing, it is important to prevent clogging in the pipes and prevent accumulation of solid particles in the toilet to avoid bad, unaesthetic view.

Filternox® FMS-WBV-MR and FMS-W&FMS-W-MR Self-Cleaning Filters are our recommended filters for greywater applications and all these models can be easily adapted into the existing system.

Contact us today for a customized filtration solution.

Filternox® offers a wide range of filtration solutions in the plastics industry. Plastic Injection Mold Cooling Water, Extrusion Mold Cooling Water, Process Water Filtration are the main usage areas in plastic industry.

Pollution that may be found in the plastics industry cooling water system is as follows:

These impurities negatively affect the operation of units such as cooling water lines, stilling basin, cooling towers which cause increase in operating-maintenance costs and low operating efficiency.

In addition, these impurities cause blockages in the molds beign therefore damaged. This interferes with the cooling required at the desired level (heat transfer) and affect production and product quality seriously. Contamination on the molds causes deformation and scratches on the surfaces of the plastic parts produced, thus reducing surface quality.

Filternox® filters remove coarse and fine particles from the water source with its automatic backwash cleaning system to secure the line and process.

Filternox® filters save water by reducing the amount of waste water and, thus reducing operating costs and enabling a more environmentally friendly system.

Filternox® offers filtration solutions for Artificial Snow Production applications.

Pollution that may occur in Artificial Snow Production Applications is as follows:

Contamination on your line can cause blockages in the nozzles, causing damage to the machines and affecting the production of the artificial snow at the desired level adversely.

Filternox® filters remove coarse and fine particles from your water source with its automatic backwash cleaning system to secure your line and process.

Filternox® filters save water by reducing the amount of waste water and, thus reducing your operating costs and enabling you to have a more environmentally friendly system.

Filternox SPT-WBV-MR and FMS-WBV-MR Self-Cleaning Filters can be easily integrated into your system.

Contact us today for a customized filtration solution.

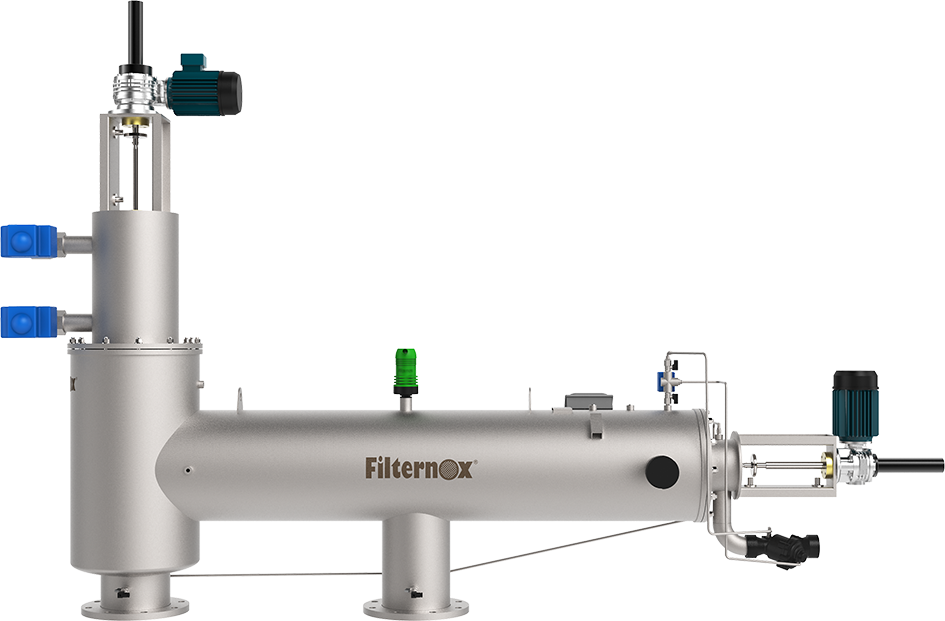

Filternox® FMS-WBV-MR models are motorized compact filters designed for dealing with high dirt loads and low liquid flow rates.

With their specially developed double effect self-cleaning system consisting of brushes and vacuum nozzles, Filternox® FMS-WBV-MR filters achieve an exceptional performance and offer a permanent and definitive solution for variable high dirt load applications and low flow rates.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 100-150l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 30 – 40 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 1.5 bar | Adjustable |

For different pressure and material requirements, please contact us.

A presentation comparing Filternox® filters with conventional sand filters.

Upgrade your sand filters to automatic Filternox filters and begin saving on operational costs today. Contact us with details about your filtration needs and we will surely get back to you; with a custom solution if required.

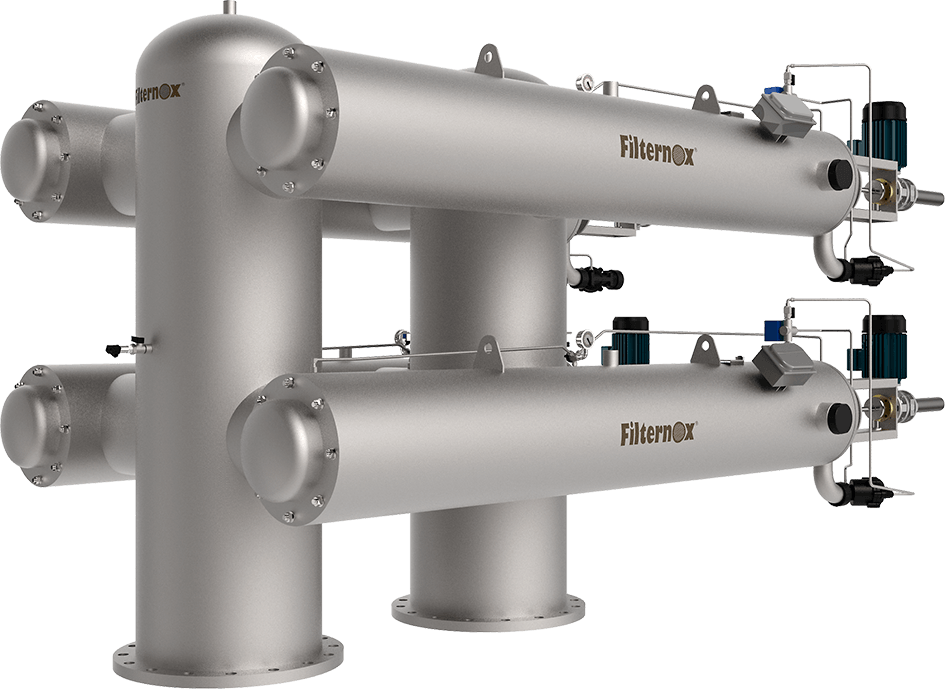

PTR models of Filternox® filters have three independent fine screen modules for one inlet-outlet. These models provide larger filtration area compered to PTW models and are suitable for filtration of water with high flow rates and high amounts of particles.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 150 – 800 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| 10 bar (16-25 bar optional) | 20 – 30 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

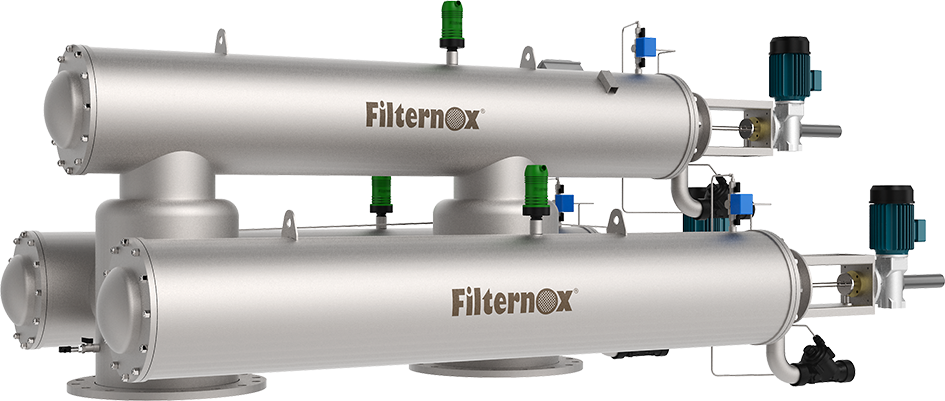

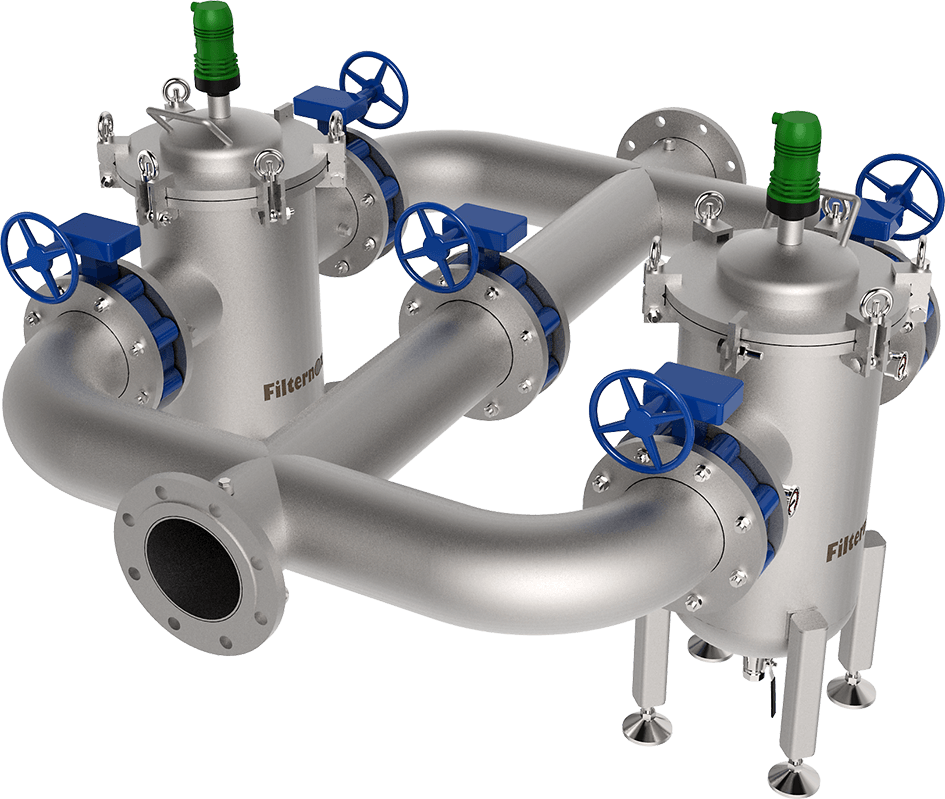

Filternox® PTW models have two independent fine screen modules for one inlet-outlet and includes a protective coarse screen which is cleaned manually. These models provide larger filtration area compared to PFH models and are suitable for filtration of water with high amounts of particles.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 150 – 800 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| 10 bar (16-25 bar optional) | 20 – 30 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

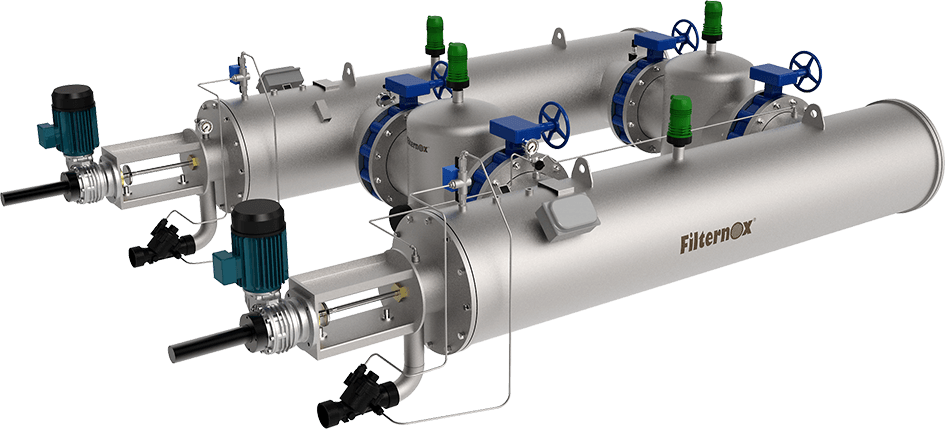

KTW models of Filternox® have an extra automatic self-cleaning system for coarse screen and consists of two independent operating fine screen modules. Suitable for sea, lake and river water filtration systems.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 150 – 800 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| 10 bar (16-25 bar optional) | 20 – 80 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

Filternox® PQR models have four independent fine screen modules for one inlet-outlet. These models provides largest filtration area compared to PTW and PTR models, they are convenient for the filtration of the water with high flow rates and high amounts of particles.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 150 – 800 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| 10 bar (16-25 bar optional) | 20 – 30 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

Filternox® FMS-V-MR filters are motorized compact designed models which are perfectly suitable for use in a wide range of application areas with low liquid flow rate and low filtration requirements.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 40-50l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 5 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 15 – 20 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 1 bar | Adjustable |

For different pressure and material requirements, please contact us.

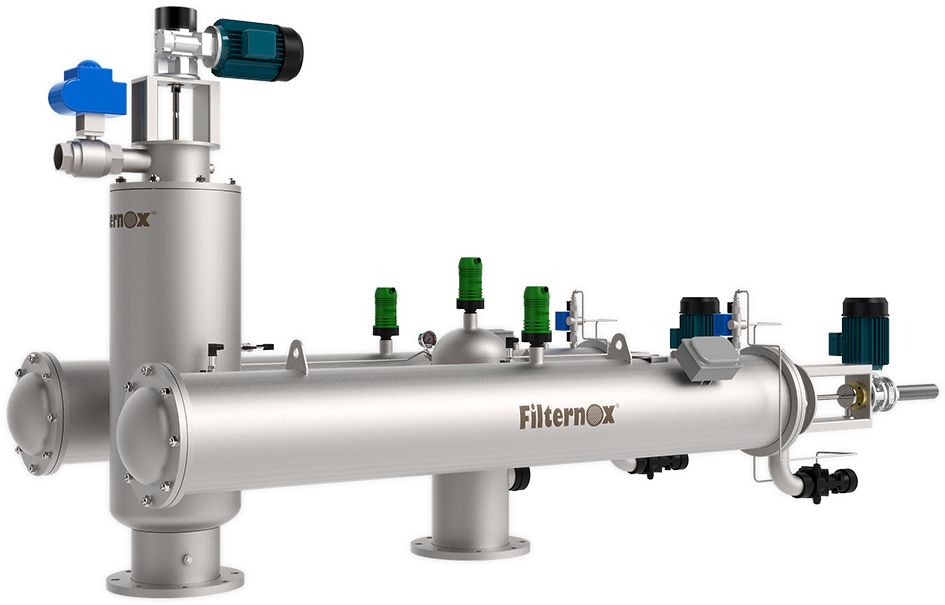

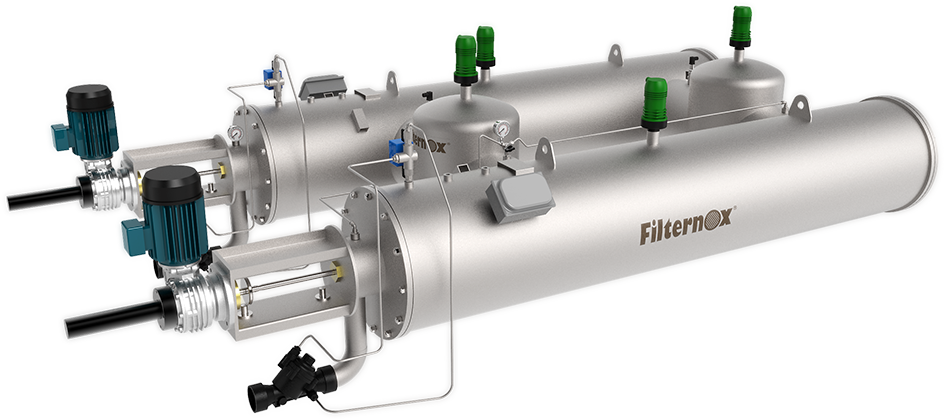

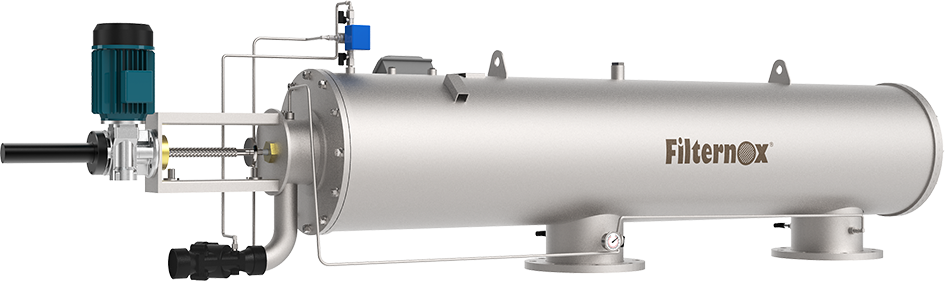

Filternox® SPT-WBV-MR, SPT-SBV-MR and SPT-PBV-MR model filters are a result of years of experience and research & development in the field.

Designed especially for river and sea water sources with very high dirt loads, SPT-WBV-MR is able to filter both large and small particles simultaneously in the same filter body.

With its specially developed dual self-cleaning system that is made of brushes and vacuum nozzles, Filternox® SPT-WBV-MR filters achieve an exceptional performance and offer a permanent and definitive solution for variable high dirt load applications.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 200 – 400 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 40 – 60 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

Introduction Document Model Brochure & Dimensions

Filternox® PTW models have two independent fine screen modules for one inlet-outlet and includes a protective coarse screen which is cleaned manually. These models provide larger filtration area compared to PFH models and are suitable for filtration of water with high amounts of particles.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 150 – 800 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| 10 bar (16-25 bar optional) | 20 – 30 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

Filternox® BMF manual cleaned models are manufactured to meet the capacity, fluid type, temperature, pressure and micron rating requirements of specific installations.

BMF-TW provides uninterrupted filtration with up to 45000 cm2 filtration area for high capacity systems.

| Body Material | Max. Operating Temperature | Max. Operating Pressure |

|---|---|---|

| AISI 304L, AISI 316L | 90°C | 10 bar (16-25 bar optional) |

| Screen Material | ||

| AISI 316L |

For different pressure and material requirements, please contact us.

Filternox® PFH-MR models are supplied with manual coarse screen and motor for low pressure and heavy duty industrial filtration applications.

Filternox® PFH-MR models, with their stainless steel construction and higher filtration surface area provide excellent performance in low pressure industrial applications. PFH-MR models are especially convenient for side-stream and full flow cooling tower filtration.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 100 – 200 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 20 – 30 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

Automatic Self-Cleaning SFH-P models are supplied without protective coarse screen and suitable for low flow applications in industrial plants, local irrigation systems and domestic usage where water does not containing coarse particles.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 80 – 120 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 15 – 20 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

SPT-MR, like all Filternox® Motor Reducer models, provides:

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 100-120 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 20 – 30 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

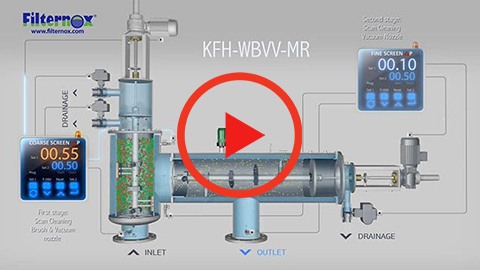

Absolute solution for all kinds of water sources with very high dirt loads.

Automatic self-cleaning KFH-WBVV-MR filters are ideal and provide permanent solution for sea water and surface water filtration with their rust-proof construction.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 200 – 400 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 40 – 60 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 2 bar | Adjustable |

For different pressure and material requirements, please contact us.

Designed for all types of fluids with low or high flow capacities.

SPECIAL BMF is suitable for high temperature and/or high pressure applications in a wide range of filtration levels.

| Body Material | Max. Operating Temperature | Max. Operating Pressure |

|---|---|---|

| AISI 304L, AISI 316L | 90°C | PN10 / PN16 |

| Screen Material | ||

| AISI 316L |

For different pressure and material requirements, please contact us.

Filternox® Automatic Self-Cleaning Filters perform successfully in many applications.