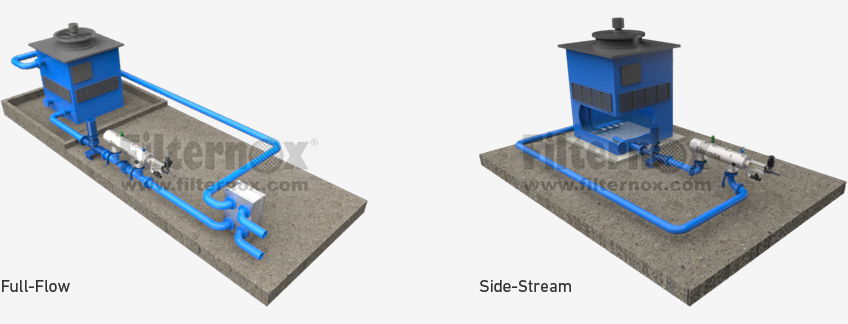

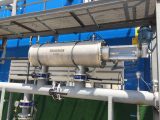

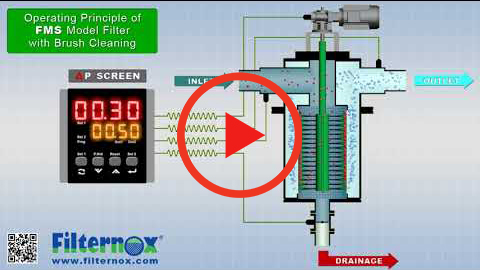

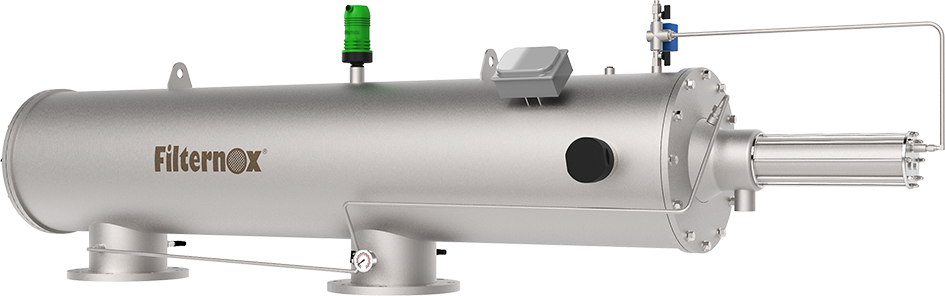

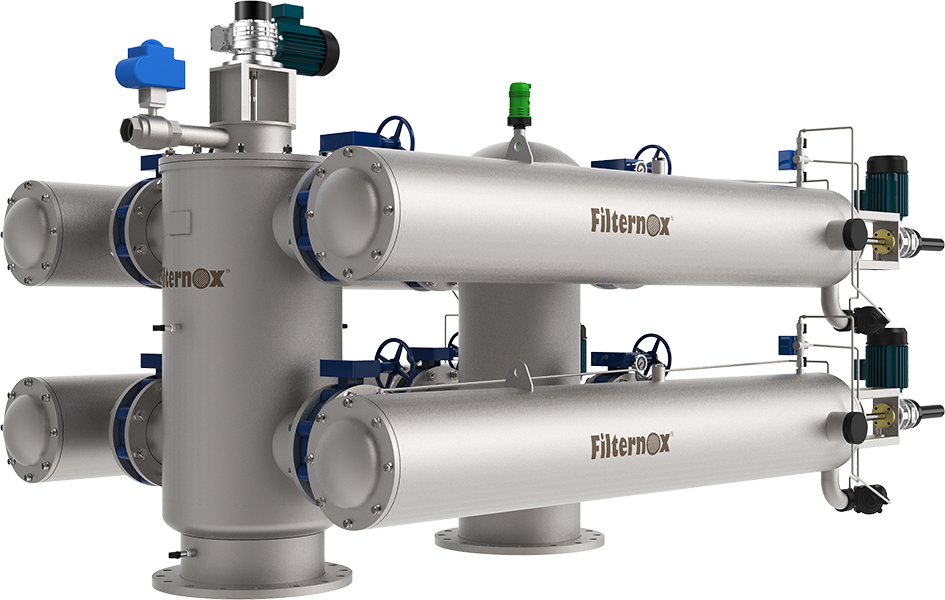

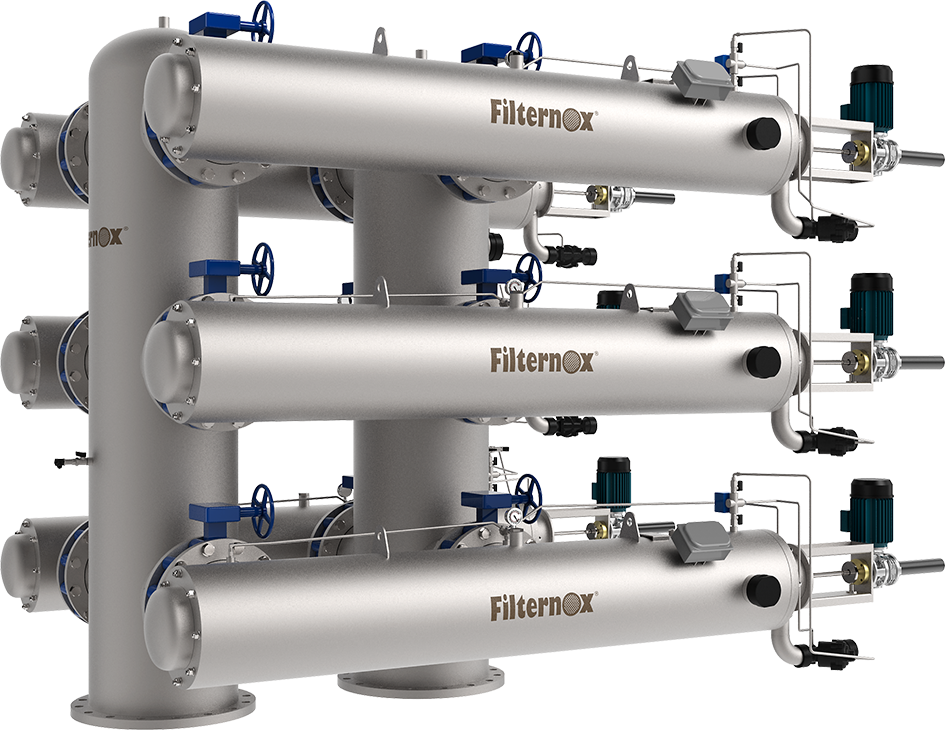

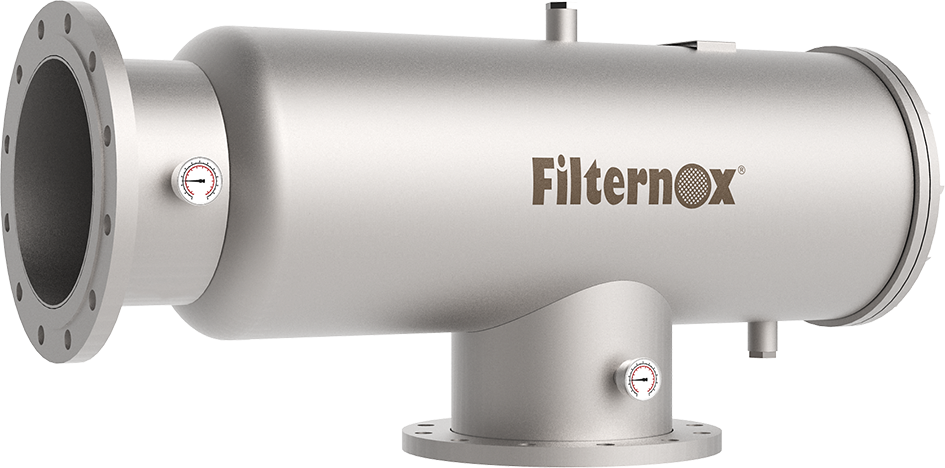

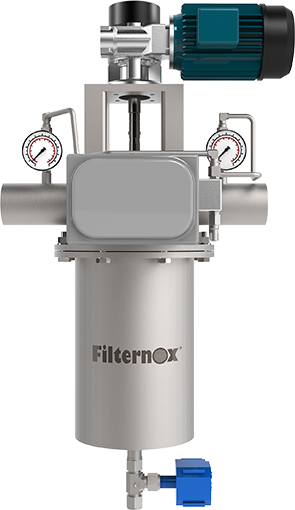

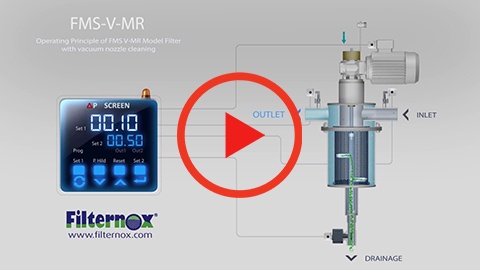

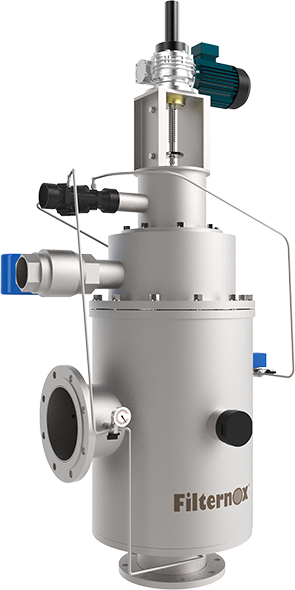

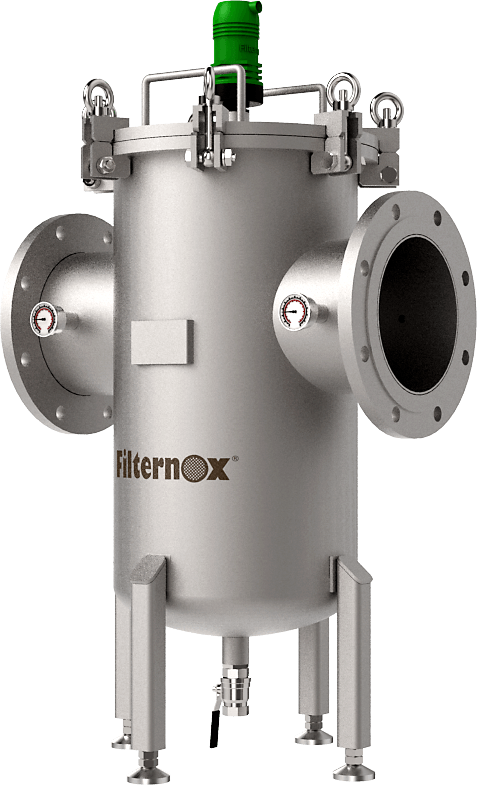

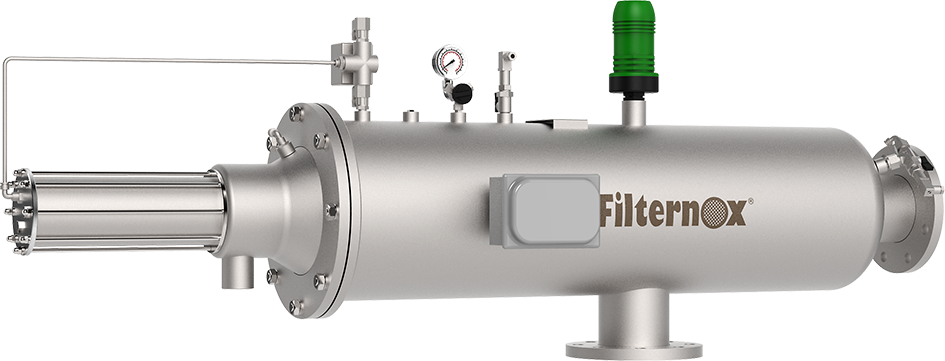

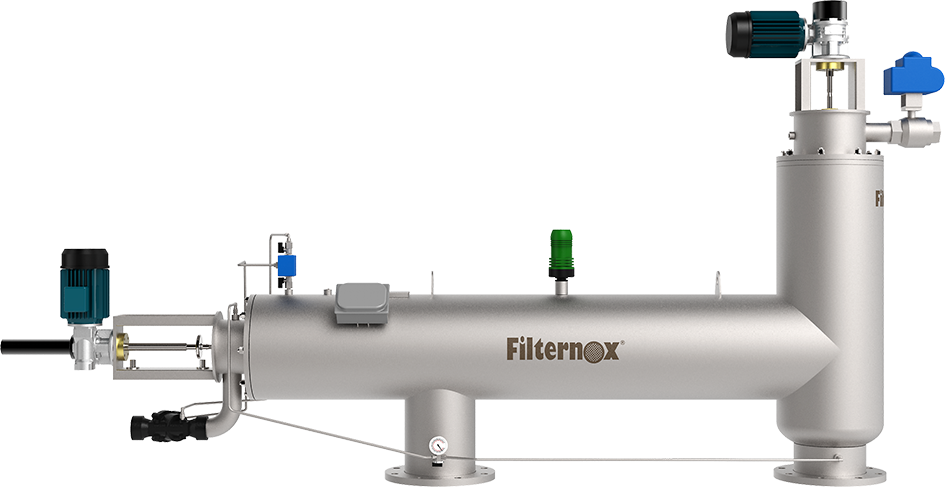

Filternox® ACF-W-MR, equipped with a brush cleaning system, provides a simple and efficient solution for prefiltration and fine filtration requirements. ACF-W-MR filters are suitable for use in a wide variety of liquid filtration applications.

ACF-W-MR models have the flexibility to be mounted directly on the pipeline, either horizontally or vertically, as well as online or inline; providing high capacity filtration with minimum footprint.

| Body Material | Max. Operating Temperature | Back-Flush Water Consumption |

|---|---|---|

| AISI 304L, AISI 316L | 60°C / 90°C | 200 – 400 l / back-flush |

| Screen Material | Headloss at Max. Flow Rate | Fine Screen Range |

| AISI 316L | 0.2 bar | 10 – 3000 micron |

| Max. Operating Pressure | Back-Flush Time | Control System |

| PN10 / PN16 | 20 – 40 s | Electric |

| Min. Inlet Pressure Required During Back-Flush | rpm of Cleaning Mechanism | |

| 1 bar | Adjustable |

For different pressure and material requirements, please contact us.

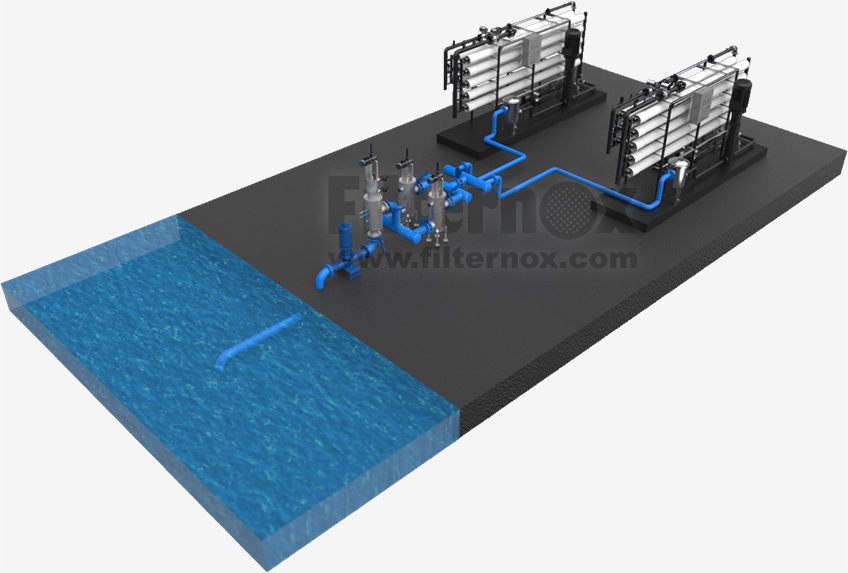

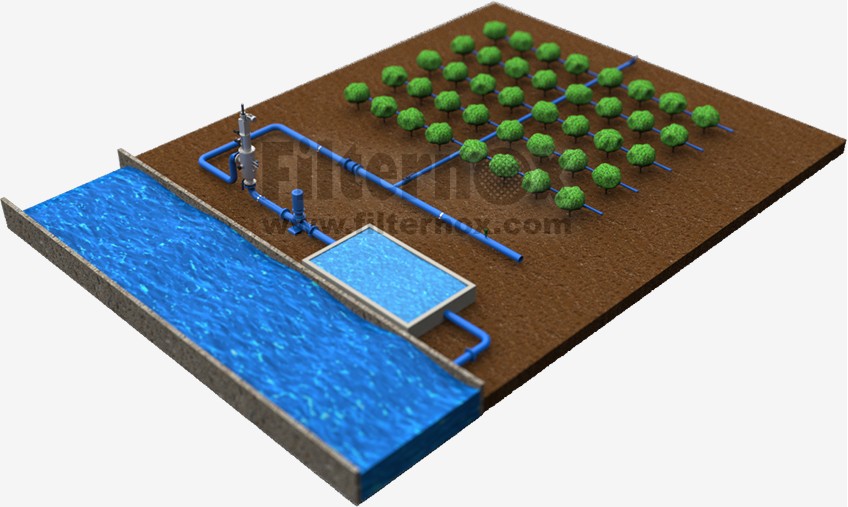

Filtration of well water is becoming one of the most important forms of filtration in the environmentally changing world. High carbon emissions along with the increasing greenhouse effect have dramatically reduced underground water supplies. This in turn, increases the amount of both organic and inorganic contaminants in the well water that is pumped through pipelines and other systems, creating the need of filtering well water.

Filtration of well water is becoming one of the most important forms of filtration in the environmentally changing world. High carbon emissions along with the increasing greenhouse effect have dramatically reduced underground water supplies. This in turn, increases the amount of both organic and inorganic contaminants in the well water that is pumped through pipelines and other systems, creating the need of filtering well water.